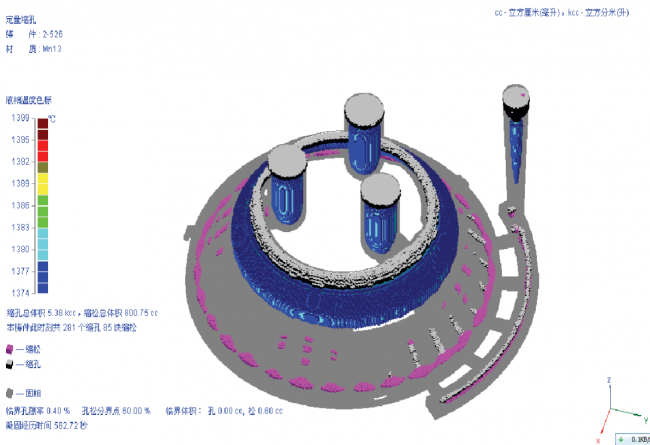

Cone Crusher Liners Melting Process

Cone crusher liners are the most important wear parts for cone crusher. The cone crusher liners melting process is the key to get a long time span life. At present, many factories use intermediate frequency furnaces to melt high manganese steel. In order to obtain high-quality cone crusher liners castings production plants, the following points…