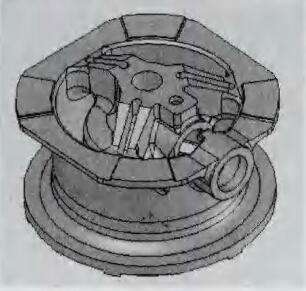

New Design Ductile Iron Jaw Plates

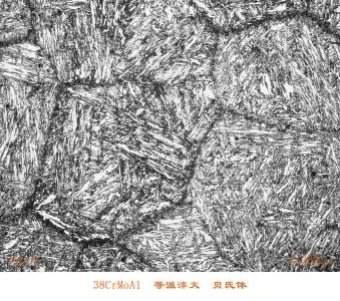

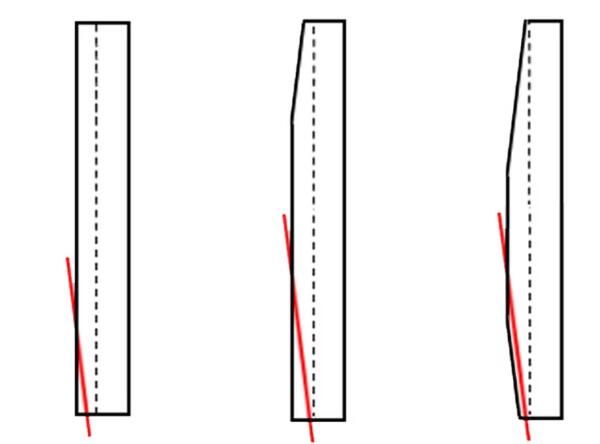

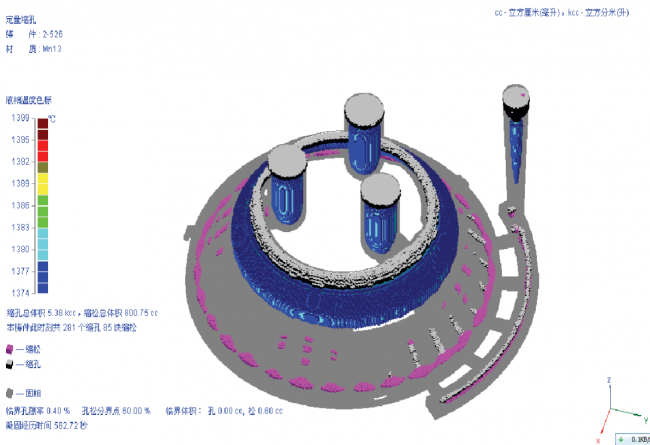

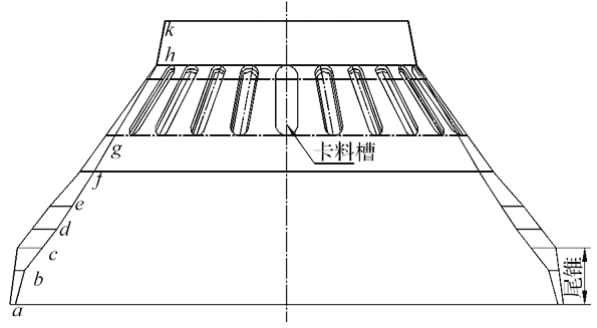

Analysis of the force and main failure forms of jaw plates The jaw crusher fixed jaw crushing liner produced by our company is mainly used for the rough and medium crushing of hard materials. During the working process, it bears the frictional force of the material, huge crushing force and impacts squeezing load. The working…