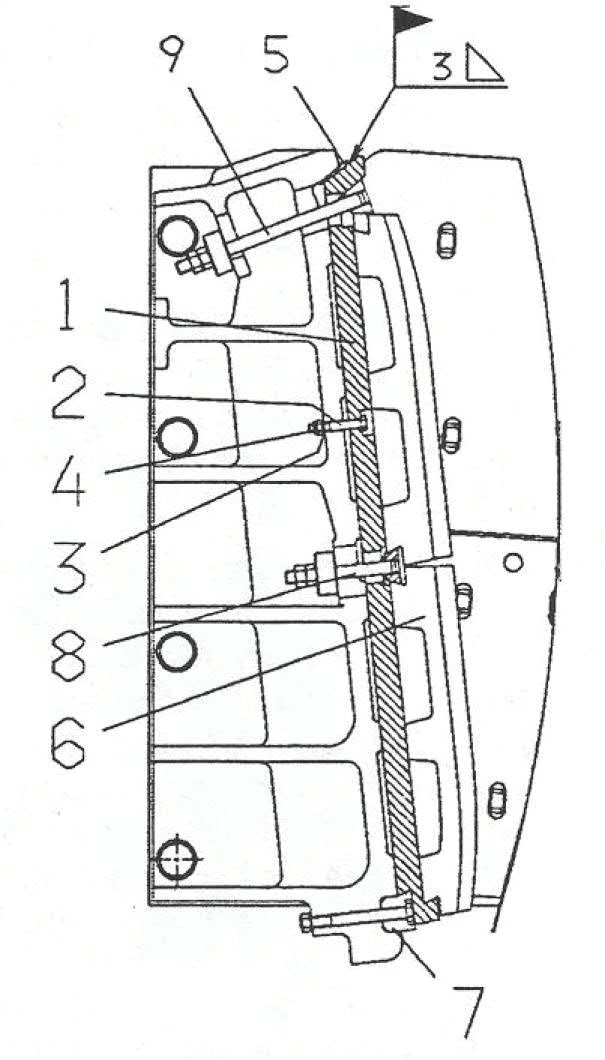

Exchanging jaw crusher wear plates

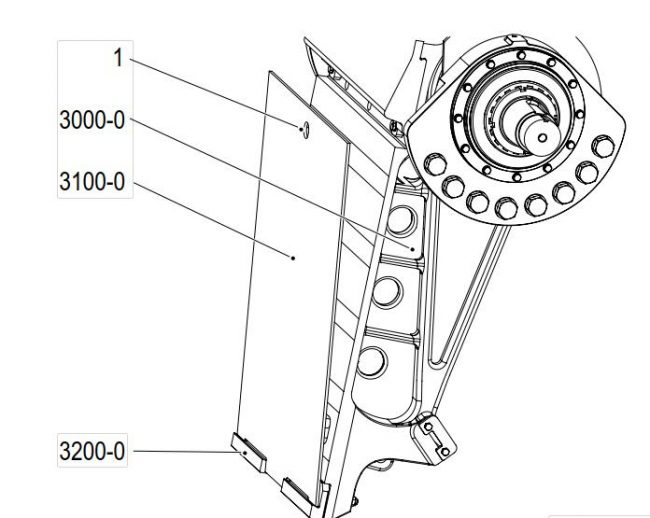

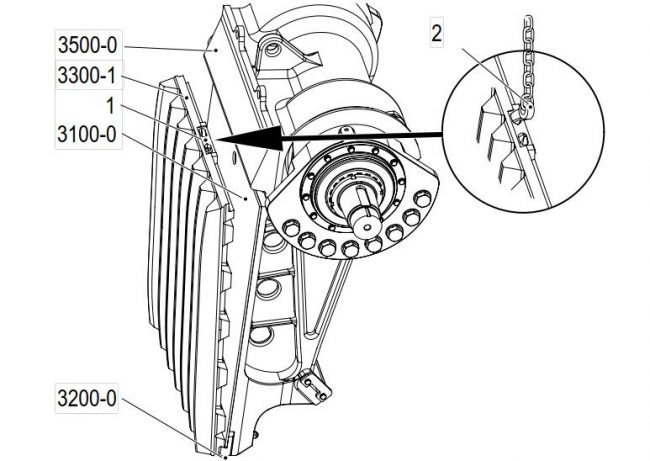

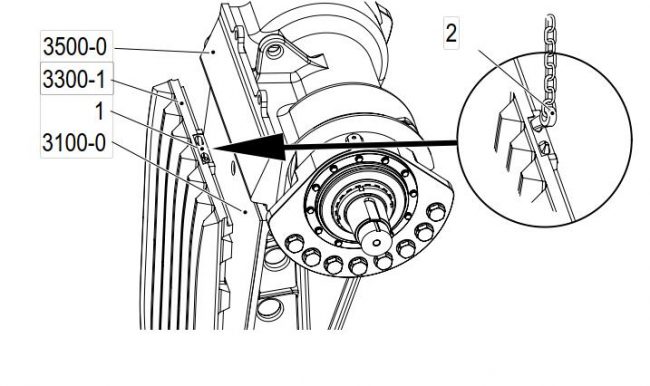

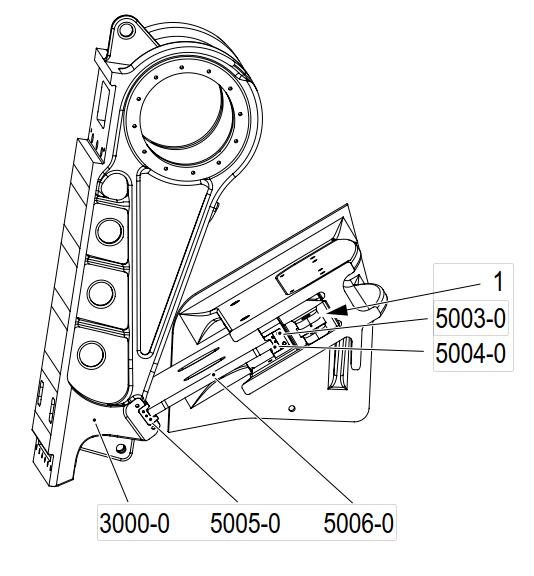

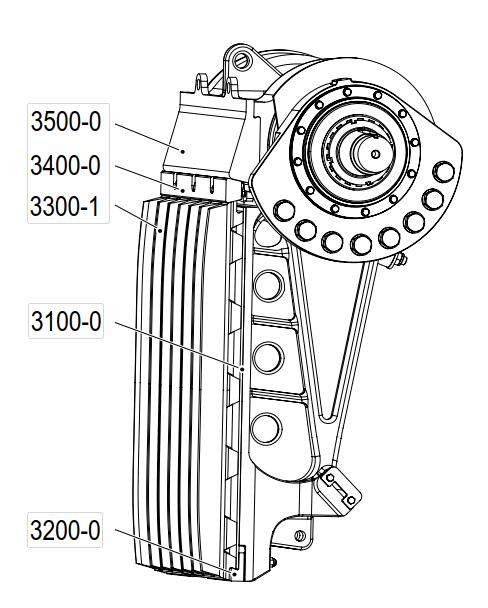

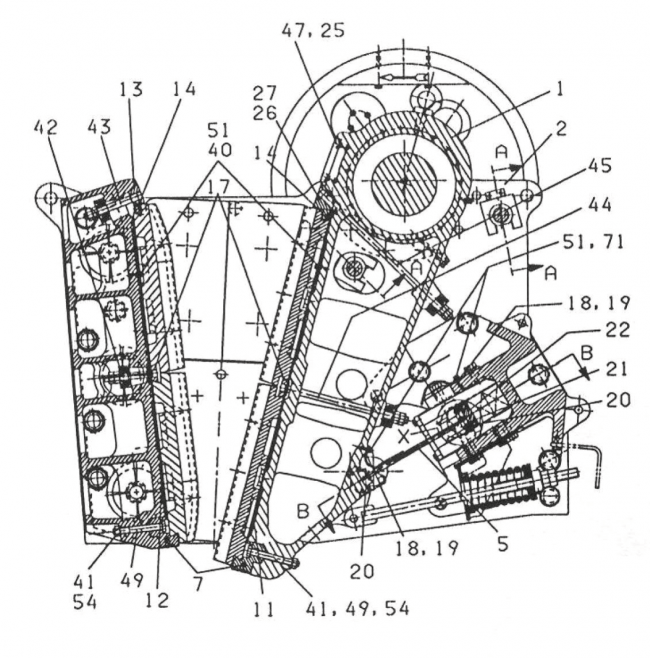

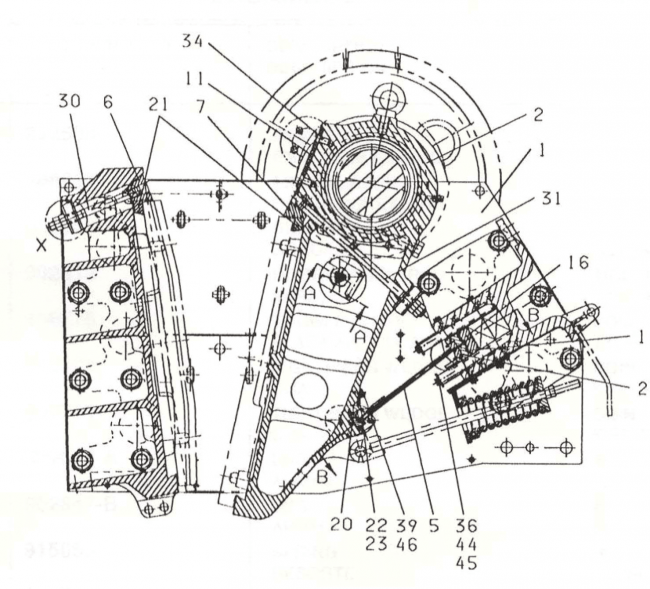

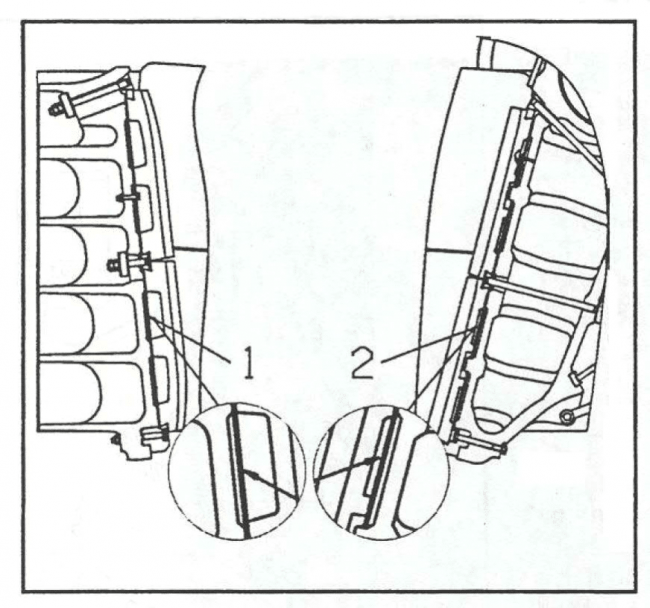

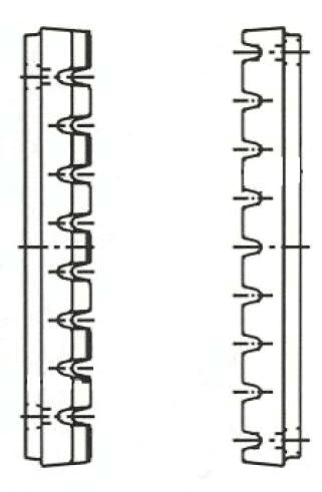

How to exchange jaw crusher wear plates? What needs notice when exchanging jaw crusher wear plate? 3000-0 Jaw (moving) 3100-0 Wear plate 3200-0 Support bar 3200-1 Lifting eye Recommended tools: Crow bar, Lifting tackle, and chain Mobile crane The following wear parts are required: New jaw crusher wear plates New side wear plates Some things…