Our customer, The Three Gorges, who have 2 sets of 50-65MK-Ⅱ gyratory crushers. This model was put into operation in August 1999. After the operation, all units responded normally. And because of its large crushing ratio and high productivity, it has become the main equipment for artificial sand and stone processing in this project. However, one of the main shafts of the crusher broke during the crushing operation until November 14, 2001. The theoretical operating time was only two years and three months. However, the actual production status of the project department is that two types of equipment are used one at a time. No two have ever run together. Therefore, a more realistic theoretical operating time should be more than one year. Although according to the contract, the factory’s main axis commitment guarantee period is 18 months, and the Three Gorges Xia’anxi Sandstone Project Department has also been entangled with the factory representative of Svedala Company for more than 2 months based on the contract, but the final reason is Sufficient and failed to get the factory’s compensation. In fact, according to the use of many similar machine types at home and abroad and the factory’s original remodeling of the device, the main shaft cannot be broken in such a short period of time. It is obvious and easy to see that the main shaft is abnormally fractured. At this time, it was also at the peak time of the concrete pouring of the Three Gorges Dam. After the main shaft of this breaker broke, the condition of the other one also caused us to start worrying. In case the other one has the same situation in a short period of time, then the results are simply not dared to imagine. Because the main shaft import price is as high as 2.3 million yuan, and the delivery period is also longer (the fastest is 6 months). In addition to the design flaws of the main shaft itself, the project department rejected the import plan of the main shaft, decided to study the technical capacity of the organization in Malaysia, and try the possibility of its national production.

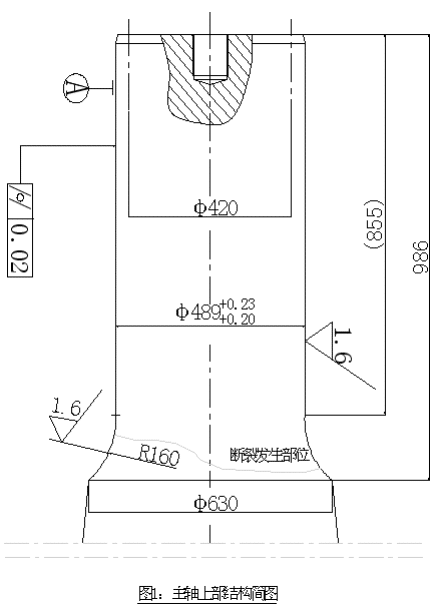

In the subsequent dismantling and inspection, we found that the fractured part of the main shaft occurred in the arc transition area of the upper shaft diameter Φ489 to the shaft diameter Φ630, and this transition area was originally a place where the stress should be relatively concentrated. By taking a sample of the fracture and analyzing it by scanning electron microscopy, the fracture surface is the fatigue fracture caused by the main shaft reaching the effective time for its use, rather than the brittle fracture caused by the external force. After our full analysis and demonstration, we came to the conclusion that this model is a modification of the 42-50 type rotary breaker. Except for the extension of the main shaft and the increase of the feed diameter, the rest of the positions have not been changed accordingly. Therefore, due to the increase in the diameter of the feed, the crushing ratio of the machine is larger than that of the 42-50 type. Therefore, the crushing force supported by the main shaft has been increased, but the diameter of the main shaft has not been increased accordingly. At the same time, as the length of the main shaft is lengthened, the bending moment moments to which the broken point of the main shaft is correspondingly increased. From the actual situation of the broken motion, the arc transition area of the main shaft is the area where the bending moment of the shaft is the largest, and the area where the stress is relatively concentrated. Therefore, it is also the weakest area of the entire main shaft. If the main shaft breaks due to the inability to withstand external forces, the cracked area should be in the weak area. See the following picture:

Gyratory crusher main shaft drawing

After finding the main reason for the fracture of the main shaft, we began to study how to reduce the probability of the main shaft breaking. To prevent the fracture of the main shaft, in addition to controlling the diameter of the raw material feed, increasing the bending strength of the main shaft and reducing the stress concentration coefficient of the main shaft crossing the arc area are two very effective paths. To increase the bending strength of the main shaft, in the case where the length of the main shaft cannot be changed, it is necessary to increase the size of the upper shaft diameter and the radius of the transition arc. However, increasing the size of the upper shaft diameter of the main shaft will bring a series of assembly problems of other related parts, which actually won’t work. Therefore, it is more feasible to increase the rounded corner size of the transition arc. And to reduce the coefficients in the stress set of the main shaft can only be done on the transitional arc fillet size. Theoretically, you can improve the main axis stress centralization coefficient by increasing the crossover arc fillet size. You can only know if you can improve it by detailed calculations; increase the main axis crossover arc area’s strength and reduce the stress on the surface. And through our detailed calculations, we have determined that we can increase the size of the main shaft crossing arc from R160mm to R285mm, without affecting the assembly of other parts. As the ratio r / d = 160/489 = 0.32> 0.25 of the original round arc fillet dimension r to the small-end shaft diameter d of the main shaft, it is known from the Mechanical Design Manual that when r / d is greater than 0.25 Simply increasing the fillet size of the transition arc can no longer reduce the fatigue notch stress coefficient in this area. Therefore, the increase in the corner size of the transition arc has not changed the situation of the stress set in the area. However, by increasing the rounded corner size of the crossing arc, the radial cross-sectional size of the main shaft can be increased. Therefore, the bending strength of the main shaft can be enhanced. And by increasing the strength and surface accuracy of the arc crossing zone of the main shaft, the stress concentration in the zone can also be reduced. In this way, the bending resistance of the arc crossing zone of the main shaft can be improved, thereby reducing the probability of fracture in this zone.

Therefore, we have decided to increase the rounded corner size of the main shaft crossing arc to R285mm in order to improve the bending strength and stress concentration in the main shaft crossing arc area, and at the same time, increase the precision of the main shaft crossing arc area.

It is easy to see that increasing the size of the main shaft crossing the arc fillet will certainly increase the bending strength of the main shaft, so the detailed check calculation of this article is omitted.

In addition, to prevent the main shaft from cracking, it can also be achieved by changing the material of the main shaft to improve the overall mechanical properties of the main shaft, so as to achieve the purpose of improving the main shaft’s overall toughness and enhancing the bending strength of the main shaft. Then we can conduct sample analysis and experiments on the material and mechanical properties of the fractured main shaft, and compare them with the mechanical properties of alloy structural steels of different brands in the country to find materials with better and better performance. If it can be found, then the conditions for the main shaft country’s production will basically be in place.

Gyratory Crusher Main Shaft Material Selection

By taking samples and chemical analysis, the main chemical components are as follows:

| Element | C | Si | Mn | P | S | Cr | Ni | Mo | V | Cu |

| Content % | 0.42 | 0.27 | 0.98 | 0.009 | 0.005 | 0.67 | 0.57 | 0.25 | 0.05 | 0.22 |

After checking the “Mechanical Design Manual” and comparing it with our domestic alloy structural steel grades, its chemical composition is similar to 40CrMnMo.

By sampling and performing mechanical performance tests, the actual mechanical properties of this gyratory crusher main shaft are as follows:

| tensile strength (MPa) | Yield point(MPa) | Elongation (%) | Rate of reduction in area (%) | Impact power(J) | Hardness (HB) | |

| Test 1 | 992 | 854 | 12 | 51 | 56 | 209 |

| Test 2 | 1006 | 866 | 11 | 54 | 60 | 207 |

| AVG. | 999 | 860 | 11.5 | 52.5 | 58 | 208 |

After reviewing the “Mechanical Design Manual” and consulting relevant domestic manufacturers, there are mainly four types of materials used in the main shafts of shredders and elevators in our country. These are: 20CrNiMo, 40CrNiMoA, 40CrMnMo, 42CrMo. They have the same mechanical properties as the 42CrMo.

| Material | tensile strength (MPa) | Yield point(MPa) | Elongation (%) | rate of reduction in area (%) | Impact power(J) | Hardness (HB) |

| 20CrNiMo | 980 | 785 | 9 | 40 | 47 | ≤219 |

| 40CrNiMoA | 980 | 835 | 12 | 55 | 78 | ≤269 |

| 40CrMnMo | 980 | 785 | 10 | 45 | 63 | ≤217 |

| 42CrMo | 1080 | 930 | 12 | 45 | 63 | ≤247 |

20CrNiMo has better forging and heat treatment properties. When using carburizing and quenching processes, it can have the characteristics of good toughness, high strength, and wear resistance of the joint with the bearing. Small-type rotary breakers are better to use. They should be used very rarely in large-sized rotary breakers. In particular, this type of structure with a bushing on the upper end does not necessarily require the use of carburizing and quenching processes.

40CrMnMo can be applied to the main shafts of large breakers and elevators. It has good hardenability, high strength, and toughness. If it can meet the performance standards, it should be a good choice. However, this material is extremely sensitive to hydrogen and easily generates hydrogen embrittlement, that is, white spots. It is extremely difficult to control in the production process, so it is rarely used;

42CrMo is widely used in the main shafts of large breakers and elevators. It has high strength and good toughness. It can be used to make the main shaft of the breaker, but its toughness is slightly lower than 40CrNiMoA;

40CrNiMoA is also widely used in the main shafts of large breakers and elevators. It has good hardenability, high strength, and toughness. The main mechanical properties are better than the original breaker shaft. And its production process is mature and mechanical performance is stable. It should be very correct to replace the original shaft material.

Therefore, after the above-mentioned analysis and comparison, and consulted the relevant experts, we finally chose 40CrNiMoA as the material of the main country.