The large impact crusher has the advantages of simple structure, large crushing ratio, and high efficiency. It is widely used in mining, cement, metallurgy, electric power, refractory materials, glass, and chemical industries. The crusher blow bars are one of the keys and easy-to-wear parts of the large impact crusher. It is fixed to the rotor of the crusher with a wedge. During the operation of the crusher, a high-speed rotating rotor drives the crusher blow bars to break the crushed ore at a linear velocity of 30 to 40 m / s. The block size of the ore is less than 1500m m, and the wear is very serious. The impact force is very large, so it is required that the crusher blow bars have the high abrasion resistance and impact resistance.

Although the traditional high manganese steel has higher toughness, the wear resistance is not high, and the wear consumption is too large. Although ordinary high chromium cast iron has a very high hardness, it is not tough enough and is easy to break. Aiming at the working conditions and structural characteristics of the large impact crusher wear parts, we developed a high chromium cast iron plate with high comprehensive wear resistance based on the existing ordinary high chromium cast iron by optimizing the composition design and heat treatment process. The service life is more than 3 times of ordinary high manganese steel.

High Chromium Crusher Blow Bars Material Design

Carbon Element

Carbon is one of the key elements that affect the mechanical properties of materials, especially the material’s hardness, and impact toughness. The hardness of the material increases significantly with the increase in carbon content, while the impact toughness decreases significantly. With the increase of carbon content, the number of carbides in high chromium cast iron increases, the hardness increases, the wear resistance increases but the toughness decreases. In order to obtain higher rigidity and ensure sufficient toughness, the carbon content is designed as 2.6 %~ 3%.

Chromium Element

Chromium is the main alloy element in high chromium cast iron. As the number of chromium increases, the type of carbides changes, and the hardness can reach H V 1300 ~ 1800. As the amount of chromium dissolved in the matrix increases, the amount of retained austenite increases and the hardness decreases. In order to ensure high wear resistance, controlling C r / C = 8 ~ 10 can obtain a larger number of broken network eutectic carbides. At the same time, in order to obtain higher toughness, the chromium content is designed to be 25- -27%.

Molybdenum Element

Molybdenum partially dissolves into the matrix in high chromium cast iron to improve hardenability; partly forms MoC carbides to improve microhardness. The combined use of molybdenum and manganese, nickel, and copper will provide better hardenability for thick-walled parts. Because the crusher blow bars are thick, considering that the price of Ferro molybdenum is more expensive, the molybdenum content is controlled in the range of 0.6% to 1.0%.

Nickel and Copper Element

Nickel and copper are the main elements of the solid solution strengthening matrix, which improves the hardenability and toughness of chromium cast iron. Both of them are non-carbon-forming elements, and all of them are dissolved into austenite to stabilize austenite. When the amount is large, the amount of retained austenite increases and the hardness decreases. Considering that the production cost and the solubility of copper in austenite are limited, the nickel content is controlled to 0. 4% to 1.0%, the copper content is controlled at 0. 6% to 1.0%.

Silicon, Manganese Element

Silicon and manganese are conventional elements in high chromium cast iron, and their main role is deoxidation and desulfurization. Silicon reduces the hardenability but increases the M s point; at the same time, silicon hinders the formation of carbides, which is conducive to the promotion of graphitization and ferrite formation. If the content is too high, the hardness of the matrix is greatly reduced, so the silicon content is controlled to 0.4% to 1.0%. Manganese expands the austenite phase region of high chromium cast iron, solid-solves in austenite, improves hardenability, and reduces martensite transformation temperature. As the manganese content increases, the number of residual austenite increases, the hardness decreases, and the abrasion resistance is affected. Therefore, the manganese content is controlled to 0. 5% to 1.0%.

Other Elements

S. P is a harmful element, which is generally controlled below 0.05% in production. R E, V, T i are added as compound modifiers and compound inoculants to refine grains, clean grain boundaries, and improve the impact toughness of high chromium cast iron.

High chromium crusher blow bars material composition

| C | Cr | Mo | Ni | Cu | Si | Mn | S | P |

| 2.6-3.0 | 25-28 | 0.6-1.0 | 0.4-1.0 | 0.6-1.0 | 0.4-1.0 | 0.5-1.0 | ≤0.05 | ≤0.05 |

High Chromium Crusher Blow Bars Production Process

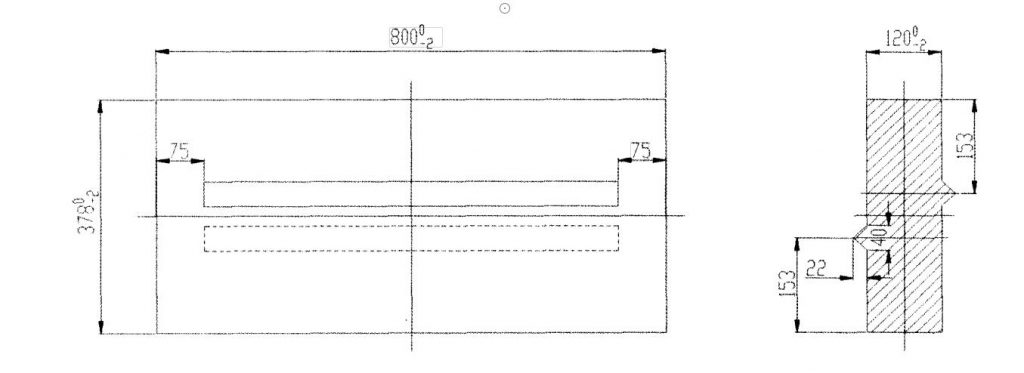

The weight of the crusher blow bar is about 285kg, and its dimensions are shown in Figure. In order to ensure the installation requirements of the blow bar, the amount of bending deformation on the plane of the blow bar is ≤ 2m m. As the surface of the blow bar is extremely high, there must not be any depressions or protrusions. To ensure the denseness of the casting, we use high-strength resin sand molding. The linear shrinkage rate is 2.4% to 2.8%. ΣF within: ΣF horizontal: ΣF straight = 1: 0.75: 1.1 to design. It adopts horizontal-type oblique pouring, and at the same time, it assists the heating and heating riser and direct external cooling iron, and the process yield is controlled at 70% ~ 75%.

High Chromium Crusher Blow Bars Size

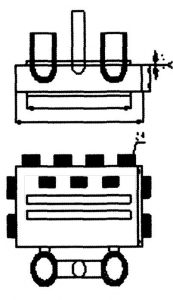

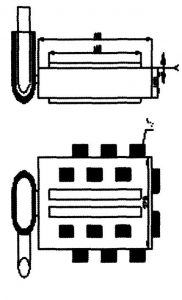

During the trial production process, we have adopted the three modeling processes of Figure 2, Figure 3, and Figure 4. After casting and grinding, it was found that the plate hammers produced in the process of Fig. 2 and Fig. 3 have different degrees of surface depression and bending deformation. The method of enlarging the riser can not eliminate the surface depression and bending deformation, which fails to meet the installation requirements.

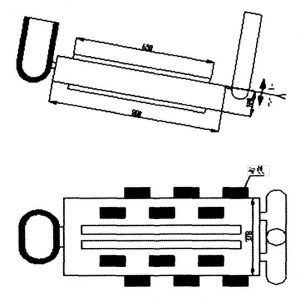

Based on the summary of the trial production experience of the molding process in Figure 2 and Figure 3, we decided to use the horizontal molding inclined casting molding process shown in Figure 4, the surface of the hammer after casting and grinding has no depression and bending deformation, and the deformation is ≤ 2m m To meet installation requirements. The specific production process is as follows: After the sand mold is horizontally made into a box, one end of the sand mold is lifted up to a certain height to form a certain tilt angle. The inclination angle is generally controlled between 8 and 20 °). The molten iron is introduced from the gate, and the molten iron first enters the cavity to reach the lowest point. It is first solidified by the chilling effect of the externally cooled iron. Pressure until the riser reaches a maximum when it is filled with molten iron, and the riser finally solidifies to achieve sequential solidification, thereby obtaining a casting with dense structure and no shrinkage.

Figure 2:High Chromium Crusher Blow Bars Modeling Process

Figure 3. High Chromium Crusher Blow Bars Modeling Process

Figure 4: High Chromium Crusher Blow Bars Modeling Process

1000k g medium frequency electric furnace (quartz sand furnace lining) is used for smelting production. Limestone + broken glass composite slagging agent is added before smelting. After most of the charge is melted, slag is removed, and then ferrosilicon and ferromanganese are added to deoxidize. The aluminum wire is discharged after final deoxidation, and the melting temperature is controlled at 1500 to 1 550 ° C.

In order to further improve the comprehensive abrasion resistance of the plate hammer, we improve the morphology of carbides of high chromium cast iron through composite modification and inoculation treatment processes, reduce inclusions, purify molten iron, refined grains, and enhance the consistency of cross-section structure and performance of thick and heavy castings. The specific operation is: preheat the ladle to 400 ~ 600 ℃, and add a certain amount of R e — A 1—B i—M g compound modifier and V —T i—Z n compound pregnant compound into the ladle before pouring.

Inoculant, molten iron is poured into the ladle, and the slag-gathering agent is thrown, so that the remaining molten slag can be quickly gathered, further purify the molten iron, and form a layer of temperature-preserving cover film, which is conducive to casting. The molten iron is sedated for 2 to 3 minutes, and the pouring temperature is controlled between 1380 and 1420 ° C.

High Chromium Crusher Blow Bars Heat Treatment

During the high-temperature quenching process of ultra-high chromium cast iron, the solubility of alloying elements in austenite increases with the increase of temperature. When the quenching temperature is low, due to the low solubility of carbon and chromium in austenite, more secondary carbides will precipitate during the heat preservation. Although most austenite can be transformed into martensite, The carbon content of the austenite and the content of alloying elements are low, so the hardness is not high. With the increase of the quenching temperature, the higher the carbon content and alloy content in the austenite, the harder the martensite formed after transformation, and the higher the quenching hardness. When the quenching temperature is too high, the carbon content and alloy content of the high-temperature austenite are too high, the stability is too high, the faster the cooling rate, the less secondary carbides precipitate, the more retained austenite, and the quenching hardness The lower it is.

With the increase of quenching and holding time, the macro hardness of ultra-high chromium cast iron increases first and then decreases. The effect of austenitizing temperature holding time on the hardness of ultra-high chromium cast iron is essentially the effect of the precipitation of secondary carbides, the closeness of the dissolution reaction and the equilibrium state on the carbon content and alloy content of high-temperature austenite. After the as-cast ultra-high chromium cast iron is heated to the austenitizing temperature, the supersaturated carbon and alloy elements in the austenite precipitate as secondary carbides. This is a diffusion process. When the holding time is too short, the precipitation of secondary carbides is too small. Because austenite contains more carbon and alloy elements, the stability is too high. Martensite transformation is incomplete during quenching, and the quenching hardness is low. With the extension of the holding time, the amount of precipitation of secondary carbides increases, the stability of austenite decreases, the amount of martensite formed during quenching increases, and the quenching hardness increases. After keeping warm for a certain period of time,

The carbon content and alloy content in the austenite reach equilibrium. If the temperature holding time is extended, the austenite grains become coarser. As a result, the amount of retained austenite increases and the quenching hardness is reduced.

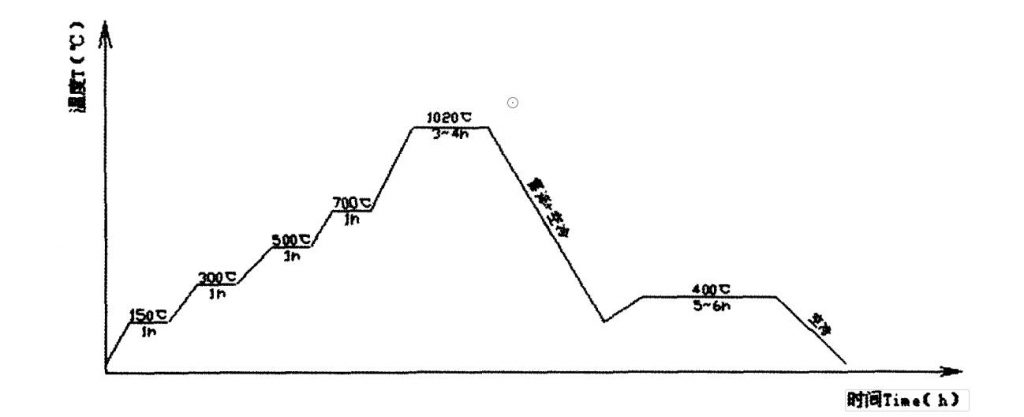

According to the national standard GB / T 8263-1999 “Abrasion Resistant White-Cast Iron Castings”, the specifications of the heat treatment process are mocked, and reference materials are provided. The quenching temperature, tempering temperature and holding time of the secondary carbide precipitation and dissolution proposed by the research determine the optimal heat treatment process for the plate hammer: 1020 ℃ (holding 3-4 h) high-temperature fog quenching, and air cooling after 3 to 5 minutes Tempering at 400 ℃ (heat for 5-6 hours, spread to air and cool to room temperature). After quenching and tempering, the matrix structure is tempered martensite + eutectic carbide M + secondary carbide + residual austenite. Because the plate hammer is thicker and heavier, in order to ensure that the casting does not crack during the heat treatment process, a step temperature rise measure is adopted. The heat treatment process is shown in Figure 5. The hardness of the plate hammer is 58 ~ 62 HRC after heat treatment, and the impact toughness is as high as 8.5J / cm.

High Chromium Crusher Blow Bars Heat Treatment