Maintenance for these parts must be carried out only by trained or authorized personnel, but the inspection can be performed by the operator.

Worn components should be replaced in good time to avoid damaging the toggle plate or toggle seats, with a consequent need for expensive repairs. Sandvik recommends exchanging the toggle plate (5006-0) and the toggle seats (5004-0), (5005-0) at the same time.

Toggle plate

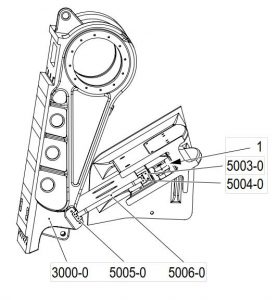

The toggle plate (5006-0) is a part of the setting adjustment system. It forms a link between the moving jaw (3000-0) and the setting arrangement (1). The toggle plate is exposed to high pressure and heavy wear and is replaceable. If the minimum discharge setting cannot be reached, this could be an indication that the toggle plate is worn down. Check it and if necessary replace the toggle plate with a new one. Stress can create cracks or bend the toggle plate. If the toggle plate shows signs of cracks or is bent it is necessary to replace it with a new one.

Toggle seat

The toggle plate (5006-0) is located by a toggle seat (5004-0), (5005-0) at each end. The toggle seats are hardened. But since they are exposed to high pressure and heavy wear, they are replaceable. If the toggle seats lose their shape it is necessary to replace them with new ones.

Jaw Crusher Setting adjustment system

- 3000-0 Jaw (moving)

- 5005-0 Toggle seat, lower

- 5006-0 Toggle plate

- 5003-0 Toggle seat holder

- 5004-0 Toggle seat, upper

- 1 Setting arrangement

Setting measuring gauge

The discharge setting is the closest distance between the jaw plates at the bottom of the crushing chamber. The distance varies with the crushing movement of the moving jaw – the smallest distance along this movement is called the CSS (closed side setting). It’s unlikely that the crusher stops when this distance is as small as possible, so the CSS must be measured on a running crusher.

A gauge for CSS, consisting of a rod with discs, is supplied with the crusher. The diameter of the smallest disc, that is in contact with both the stationary and moving jaw plate when and where the distance is as small as possible, gives an appreciation of the CSS. The disc simulates the section of a spherical or ellipsoid stone.

The measuring tool is composed of a set of rubber discs with different diameters, one rod with threaded ends, nuts, fixing washer and a nylon line for gauge lifting. When the rod is suspended by the line, it will maintain the mounted disc in a horizontal position.

Measuring instructions

Run the jaw crusher empty. Clean the feeder from process material, before measuring begins.

- Make an assumption of the diameter of disc to use. Mount it on the rod.

- Lower the measuring tool by the line along the stationary jaw plate. The disc should be in contact with two crests.

- If the measuring tool passes the bottom end of the jaw plates, the disc is too small, but if the measuring tool is stopped before it reaches the bottom end, the disc is too big.

- When the correct disc is mounted, it is in a horizontal position touching two stationary jaw plate crests and barely touching one moving jaw crest at the bottom end of the jaw plates. This means that the disc diameter is equal to the CSS.

- If a specific CSS is required, use the corresponding disc diameter and adjust the setting arrangement to obtain the required setting.

- The crusher has accessories to help to adjust the CSS to a minimum. Simply by replacing the wear plates behind the jaw plates with thicker jaw shim plates (and exchanging the support bars) the minimum CSS can be decreased.