After a long time running, jaw plates need an exchange. The following wear parts are required:

- A new fixed jaw plate

- A new movable jaw plate

Never weld external lifting eyes to the jaw plates. Always use the referred lifting cavity on the jaw plate and the lifting tool provided with the jaw crusher.

Removing jaw plates

- Remove the props between the jaws. Be aware of the weight of the jaw plate. Make sure the moving jaw is reclined so that the jaw plate will not fall forwards while releasing the jaw plate or uncovering the lifting cavity. Never stand in the crushing chamber while releasing the jaw plate or uncovering the lifting cavity.

- Release the jaw plate from the jaw by applying a crowbar to the upper edge of the jaw plate. Bend carefully.

- Position the hook of a mobile crane vertically above the crushing chamber. Make sure the crane is able to move longitudinally with respect to the jaw crusher.

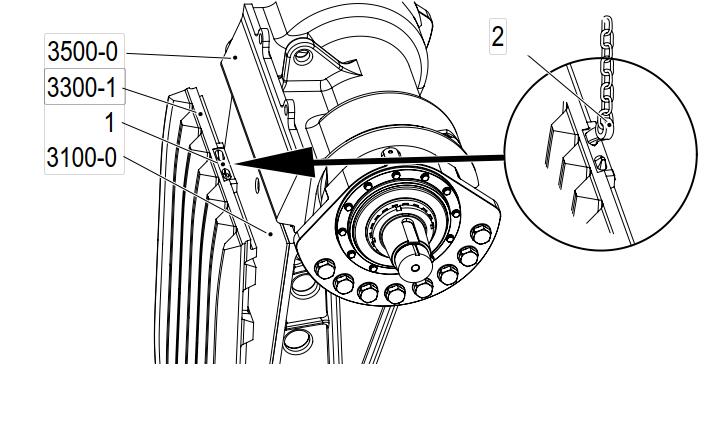

- Apply a crow bar between the jaw plate and the deflector plate (moving jaw) or front frame end (stationary jaw) to uncover the lifting cavity.

- Remove any sponge rubber strip or rags from the lifting cavity.

- Hang the lifting tool (provided with the crusher) on the hook of the mobile crane and attach the hook of the lifting tool to the lifting cavity. If the jaw plate is worn down too far, the lifting cavity can be worn away or deformed. Sandvik strongly recommends exchanging the jaw plates before this occurs.

- Take up the slack in the lifting tackle.

- Carefully lift the jaw plate out of the crushing chamber. If the wear plate is attached to the jaw plate when the jaw plate is lifted out it can come off while lifting. Keep clear of hanging loads.

- If the wear plate is attached to the jaw plate when the jaw plate is lifted out, it is necessary to fit a new wear plate.

- Place the jaw plate horizontally on the ground.

Exchanging jaw plates