Jaw Crusher Intermediate Plate

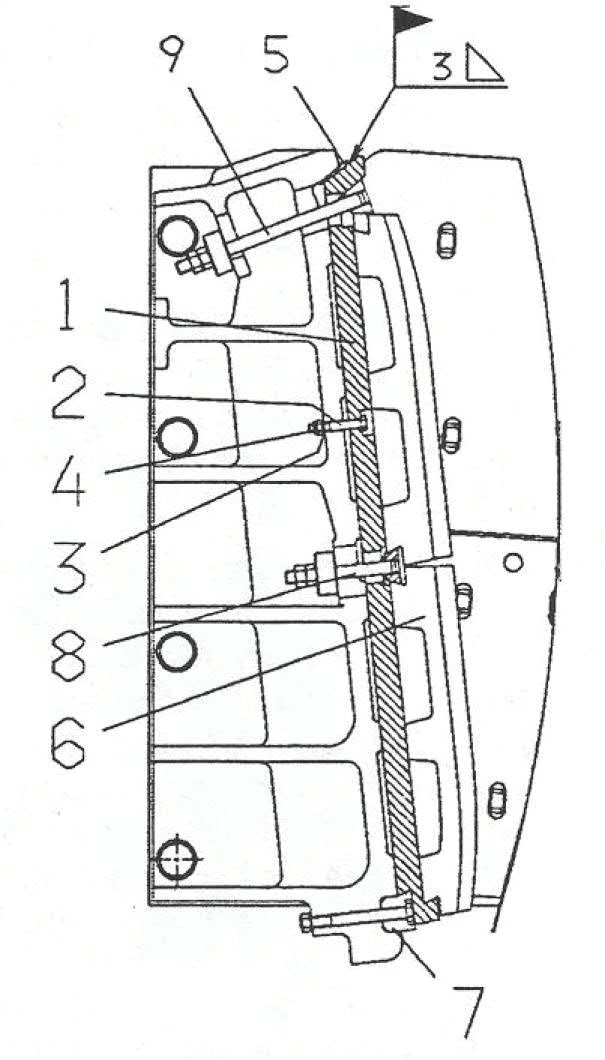

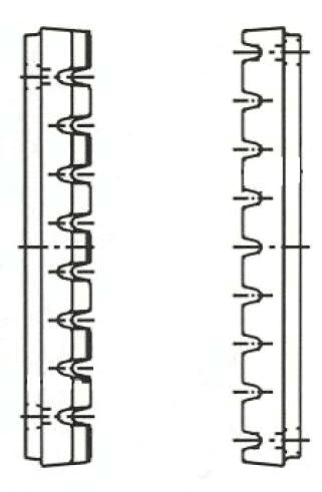

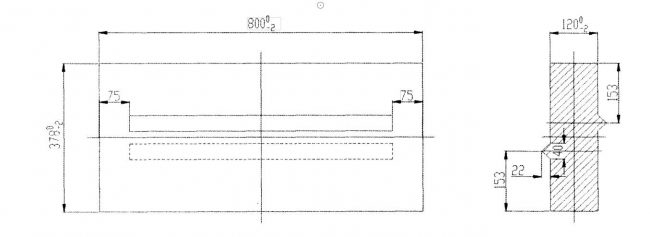

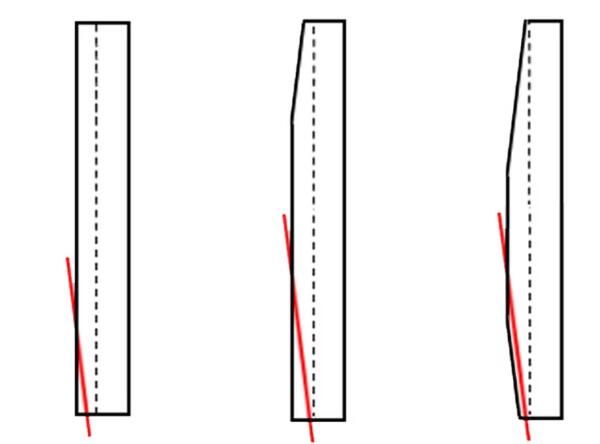

The intermediate plate is an important jaw crusher wear parts. Fitting an intermediate (backing) plate behind the fixed jaw die reduces the nip angle of the crusher. The intermediate plate reduces the feed opening and the setting range by approximately the same amount as its thickness. However, the intermediate plate does not, under normal circumstances,…