Cone Crusher Liners Heat Treatment

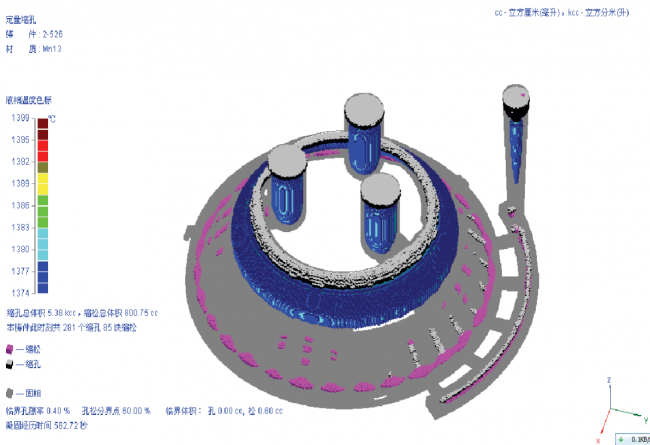

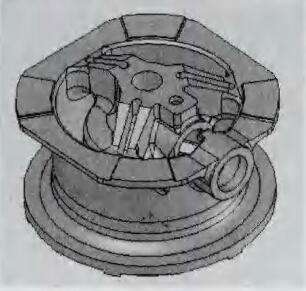

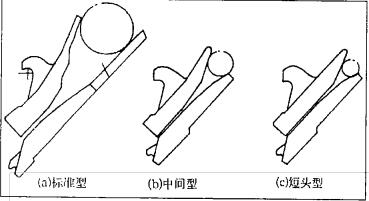

Cone crusher liners include cone crusher mantle and concave. The heat treatment is the most important step in casting cone crusher liners. How to control heat treatment? The advanced and convenient heat treatment tooling equipment is used, and the castings should be placed with the mouth facing down. The crushing wall and rolling wall castings…