Mill liners are an important component of the grinding mill. They not only protect the shell of the mill from wear and tear but also transfer energy generated by the mill motor to the grinding charge. This increases the efficiency of the mill. In this article, we shall discuss a few common types of mill liners.

Firstly, however, it should be noted that there are different ways of differentiating the types of mill liners. If you want, you can categorize them according to their design and specific functions, or otherwise, you can do so according to the material they are made up of. We shall categorize them according to the former.

Solid Liners

Solid liners are made up of fewer pieces so are comparatively easier to install. However, they wear off pretty soon so it will not be a good option for those looking for a long-serving liner. They are made up of an integral lifter and liner.

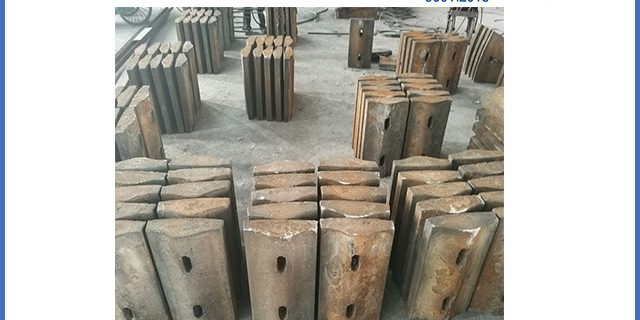

Wedged Liners

These were the most common liners in the previous era, but are no longer used due to the dangers that come along installing them.

Removable Lifters

In these kinds of mill liners one can remove just the lifter and replace it, instead of removing the entire liner. This is more cost-efficient and longer living. However, in these liners, the lifters can change orientation and damage the whole structure including the bolts that hold them.

Grid Liners

These liners are manufactured by Manganese steels, which provides us with a lot of benefits. However, along with benefits, there may be a few dangers, that come especially when inspecting the liners. To prevent that, constant hosting is required which can be quite time inefficient.

However, considering all these disadvantages, these liners are still the most economically beneficial because of their high-speed processing as compared to other mill liners and their rigorous grinding capabilities.

Integral Wave Blocks

These mill liners are usually used in ball mills, and it has become quite sophisticated with time, improving the quality of its maintenance.

High-low double wave ball mill liners

It is an upgraded version of the wave blocks mentioned above. You need to measure the face angles of this mill liner correctly or it will wear out the balls quickly, and the grinding would be significantly inefficient.

Uni-directional profiled liners

You can customize the leading and trailing profile in these mill liners according to your needs and requirements, which significantly increases the efficiency of the milling process.

The material categorization

The other way to categorize mill liners is according to the material they are made up of. They are as such:

- Rubber liners

- Magnetic liners

- Austenitic Manganese Steel liners

- High/Low Carbon Chrome Moly steel liners

- Nihard iron liners

- Chrome Moly white irons

Final Thoughts

Each of these liners has their respective uses and efficiencies according to the needs and wants of the manufacturers, and thus, each of them holds importance within the industry, though, some may hold more than others. You can consult with Qiming Machinery if you need any of the material for your use.