Welcome to the crusher wear parts selection guide. This Guide has been developed to help our customer’s personnel to expand their knowledge of Crusher Wear part options & terminology and help relay this information to end-users in a clear and logical manner.

What Is Wear?

Wear is material loss on surfaces by means of several different mechanisms. The two main wearing mechanisms in the crushing chamber are Abrasive wear & Fatigue wear.

Fatigue wear

Fatigue wear is also present as wear is subjected to multiple compression or impact loads. During the crushing cycle, gouging or high-stress abrasion is present depending on the particle size of the feed material. Between the crushing cycles when particles of feed material are sliding against wear parts, low-stress abrasion is present.

Abrasive wear

The main wearing mechanism in the crushing chamber is abrasive wearing. There are three types as the following:

Low stress or scratching abrasion

- Less work hardening on manganese

- Scratching abrasion while the material is sliding at the surface of wear parts

- No compression load

High stress or grinding abrasion

- Less work hardening on manganese

- High compression load

- Smaller particles

Gouging abrasion

- Large particles

- High impact or compression loads

- Good work hardening on manganese

Some other wear factors

Several other factors affect the wear lifetime of crusher wear parts as listed below :

Several different factors affect the wear of wear parts. Type of wear, environmental factors, crusher operating parameters, feed material, and wear part properties.

Environmental factors

- Moisture

- Temperature

Type of wear

- Adhesive

- Fatigue

- Corrosive

- Abrasive

Crusher parameters

- CSS

- Speed

- Stroke

Wear material itself

- Wear material type or chemical composition

- Wear parts manufacturer and quality

Feed

- Distribution

- Rock types and characteristics

- Wearing particles

Feed Material Properties

Two of the most notable factors in the wear of crusher wear parts are abrasiveness and crushability of feed material.

Crushability classification

Crushability indicates how easily the rock material breaks down. Difficult rock with a low crushability value requires more crushing energy than easier rocks with a higher crushability value.

| Crushability | ||||

| CLASSIFICATION | CRUSHABILITY (%) |

BOND WORK INDEX (KWH/T) |

LOS ANGELES VALUE |

UCS (MPa) |

| Very Easy | 50+ | 0 – 7 | 27+ | 0 – 90 |

| Medium | 40 – 50 | 7-10 | 22 – 27 | 90 – 150 |

| Difficult | 20 – 30 | 14 – 18 | 12-17 | 220 – 300 |

| Very Difficult | 10-20 | 18 + | 5-12 | 300 + |

Abrasiveness classification

The abrasiveness of the feed material can be determined in rock laboratories using a test for abrasiveness. The following table indicates the abrasiveness of rock based on this test.

| Abrasiveness | ||

| CLASSIFICATION | FRENCH ABRASIVENESS ( G/TON) | ABRASION INDEX |

| Non-Abrasive | 0 – 100 | 0.0-0.1 |

| Slightly Abrasive | 100 – 600 | 0.1-0.4 |

| Medium Abrasive | 600 – 1200 | 0.4-0.6 |

| Abrasive | 1200 – 1700 | 0.6-0.8 |

| Very Abrasive | 1700 + | 0.8+ |

Material properties

There are some common materials abrasiveness and crushability:

| Material Properties | ||

| ROCK NAME | CRUSHABILITY | ABRASIVENESS |

| Amphibolite | 25-46 | 30-1600 |

| Basalt | 20-44 | 500-2300 |

| Diabase | 18-44 | 450-2300 |

| Diorite | 20-36 | 400-1700 |

| Dolomite | 30-56 | 20-450 |

| Gabbro | 27-34 | 800-1700 |

| Gneiss | 30-67 | 600-1600 |

| Granite | 28-90 | 900-1900 |

| Gravel | 30-55 | 300-2500 |

| Limestone | 30-62 | 0-500 |

| Rhyolite | 16-56 | 700-1900 |

| Sandstone | 32-60 | 300-2200 |

| Quartzite | 22-65 | 1400-2400 |

Material selection for crusher wear parts

There are six kinds of wear materials for crusher wear parts:

- Manganese steel

- Martensitic steel

- Chrome steel

- Martensitic steel with ceramic insert

- Chrome steel with ceramic insert

- Manganese steel with TIC insert

Manganese steel

Austenitic manganese steel is a very tough and ductile material having a high impact toughness. Mn-steel is a rather soft material having an initial hardness of approx. 220-250 HV. The wear resistance of manganese steel is based on a work hardening phenomenon. When the surface of the Mn-steel is under heavy impact or a compressive load, it hardens from the surface while the base material remains tough. The depth and hardness of the work-hardened surface vary depending on application and Mn-steel grade. The work-hardened layer can be between 10 and 15 mm deep and hardness can be up to 600 HV in primary applications. In fine crushing applications, the work-hardened layer is thinner and hardness is usually around 350-500 HV. The Mn/C ratio and amount of Cr are not only relevant when it comes to the wear resistance of the Mn-steel. There are three grades of manganese steel for casting crusher wear parts:

- 18% Manganese. Used as standard on all jaw crushers covering the majority of quarry and recycling applications. It has an initial hardness of around 230 BHN (Brinell Hardness) and can work hard during operation to 400 BHN. 14% and 22% manganese are also available as options. These alternatives can sometimes be the better fit for your application and your business, allowing you to get the best wear possible.

- 14% Manganese. This work hardens under normal conditions and will reach a Brinell hardness of 450-500BHN. Application selection for 14% manganese is important as due to its softer initial state of 220BHN, excessive wear can be caused in abrasive and very hard rock applications. In softer rock applications such as soft limestone 14% manganese can be more effective than other grades of manganese.

- 22% Manganese. Like the 18% manganese, this material has a higher initial hardness of 248BHN. On hard rock applications, 22% manganese can offer greater wear life thus increasing uptime, and can outperform other grades of material. This can outperform the other grades of material.

Manganese steel use to cast jaw plate, cheek plate, mantle & concave, blow bars, and some other wear liners.

Martensitic steel

The martensitic steel blow bar is a good option for the widest variety of applications and is suitable where there is variable feed material. It demonstrates good impact resistance against all but the hardest rocks and shows high resistance to gouging abrasion. It is supplied at around 500 BHN and does not work hard. Martensitic steels Martensitic blow bars are less susceptible to damage than Chrome so the material feed size is only restricted by the maximum chamber feed size.

This material is used to cast crusher blow bars.

Chrome steel

The high chrome blow bar is the ideal choice for highly abrasive applications where there are no oversize high-impact rocks or recycling debris in the feed. It is not tolerant to tramp metal. It is supplied at around 650 BHN and does not work hard. The material feed size must be limited to prevent damage to the blow bars. For Chrome, this is a maximum of 300mm. High chrome blow bars have a longer lifetime than the manganese steels (3 to 4 times the manganese wear life.)

This material is used to cast crusher blow bars.

Martensitic steel with ceramic insert

The martensitic ceramic blow bars are used mainly in the recycling industry. They are designed to provide the high durability of the martensitic material combined with the excellent abrasive resistance of the ceramic insert. Martensitic Ceramic blow bars are less susceptible to damage than Chrome so the material feed size is only restricted by the maximum chamber feed size.

This material is used to cast crusher blow bars.

Chrome steel with ceramic insert

This is a composition blow bar consisting of hard ceramic particles on the wear surface in a chromium iron matrix. This composite has the effect of combining the very hard surface of the ceramic with the useful mechanical properties of chromium iron. These (chromium/ceramic) blow bars can have two to four times the life of standard mono-alloy blow bars. Chrome Iron with ceramic is a premium composite metallic matrix iron with hard ceramic alloy inserts on the wear surface. The hard alloy ceramics combined with either medium chrome or high chrome iron matrix provides a significant working life advantage over standard chrome iron bars. Whilst this material can be very successful in secondary applications, it should not be used for primary crushing or very hard and abrasive applications.

This material is used to cast crusher blow bars.

Manganese steel with TIC insert

This is a new material for casting crusher wear parts developed by Qiming Machinery. Our engineers analyze the worn parts of the parts by scanning the used parts, and then arrange the titanium carbide rods on these worn parts. The substrate is still designed with high manganese steel. This manganese steel with TIC inserts crusher wear parts span life can be 1.5-3 times than normal manganese steel parts.

This material is used to cast mantle&concave, jaw plates, and crusher blow bars.

Crusher Wear Parts Types & Selections

There are three types of crusher wear parts:

- Jaw crusher wear parts

- Cone crusher wear parts

- Impact crusher wear parts

Jaw crusher wear parts

Jaw crusher wear parts include fixed jaw plate, movable jaw plate, and some cheek plates.

- Fixed jaw plate, which installs in the jaw crusher body. Normally, it has two kinds of designs, one-piece design, and two-piece design;

- Movable jaw plate, which installs in the moving jaws. Normally, it also has two kinds of designs, one-piece design, and two-piece design;

- Cheek plates. There are some plates install on the side of the jaw crusher body, which can protect the side body do not break by crushed stone.

Crusher jaw plates selection

There are a few key points that you need to consider when selecting the correct liners for an application:

- Feed Material Type

- Feed Material Hardness / Abrasiveness

- Feed Size

- Required output

- Potential of uncrushable material in the chamber

- Required throughput

Crusher jaw plate tooth types

Different brands of jaw crushers, different jaw plate tooth types. There are some famous brands of jaw crusher plates tooth types:

- Metso jaw plates tooth type

- Sandvik jaw plates tooth type

- Terex jaw plates tooth type

Metso jaw plates tooth type

- Standard tooth. Good in gravel and non-abrasive rock; Tooth spacing ideal for fines removal; Power requirement and crushing stresses are in balance; Less slabby product; Reduced lifetime in the abrasive application.

- Superteeth tooth. General use in gravel and blasted rock; Tooth spacing ideal for fines removal; More tooth contact surface area compared to standard profile; More wearable Mn-steel than in standard jaws; Power requirement and crushing stresses are in balance; Less slabby product.

- Quarry thick + Super grip tooth. Good in blasted rock, difficult natural rock, and slippery rock; Sharp tooth profile (good grip on the rock); Power requirement and crushing stresses are in balance; Tooth spacing ideal for fines removal; Can be used when scalping is not efficient; Less slabby product.

- Super grip tooth. Good in gravel and non-abrasive rock; Tooth spacing ideal for fines removal; Power requirement and crushing stresses are in balance; Less slabby product; Reduced lifetime in the abrasive application.

- Quarry thick tooth. Good in abrasive and/or blasted rock; Fixed jaw die is 40 mm thicker than quarry jaw die (provides longer lifetime); Flat tooth profile maximizes lifetime (more surface area to crush with); More wearable Mn-steel than in standard jaws; Higher stresses and power requirements; Less space for fines to pass through (fines removal from feed material is important); Increase in the slabby product.

- Anti-slab tooth. Uneven tooth height (reduces slabs in feed material); Less slabby product.

- Quarry tooth. Good in abrasive and/ or blasted rock; Flat tooth profile maximizes lifetime (more surface area to crush with); More wearable Mn-steel than in standard jaws; Higher stresses and power requirements; Less space for fines to pass through (fines removal from feed material is important); Increase in the slabby product.

- Quarry + Super grip tooth. Good in blasted rock, difficult natural rock and slippery rock; Sharp tooth profile (good grip on the rock); Power requirement and crushing stresses are in balance; Tooth spacing ideal for fines removal; Can be used when scalping is not efficient; Less slabby product.

- Recycling tooth. Ideal for concrete, brick etc., demolition waste; Wear and crushing forces in good balance; Tooth spacing ideal for fines removal.

- Wavy-like tooth. Suitable for asphalt crushing; Wide grooves (material flows easily through the cavity)

Sandvik jaw plates tooth type

- Corrugated tooth. Suitable for less abrasive material. For feed with a lot of fines. Good for small CSS settings. Good top-size control.

- Sharp tooth. For flaky feed material with a lot of fines. Good gripping ability. Very good top-size control. Highly recommended if the AI is not too high.

- Heavy-duty tooth. For very abrasive material. Used for large CSS settings. Good top-size control.

- Wide-tooth. Good wear resistance. For feed with a lot of fines. Can be used on both fixed and moving sides.

- Coarse corrugated tooth. For abrasive material. For feed with a lot of fines. Used for large CSS settings. Good top-size control.

- Wide wave tooth. For slabby and less abrasive feed material. Feed is relatively easy to crush. Good top-size control.

Terex jaw plates tooth type

- Super tooth. Medium to hard rock application, Grips material to allow better crushing, Available in Mn18 and Mn22;

- Quarry tooth. Hard rock and high abrasive applications, Deeper tooth profile allows for extra wear, Available in Mn18 and Mn22;

- Multi tooth. Recycling applications, good grip on smooth flat surfaces, Available in Mn18;

- Standard tooth. Recycling and soft rock applications, Not available for all models, Available in Mn18.

Jaw crusher liners codes

There are some famous jaw crusher liners codes. It does not mean that Qiming Machinery has any cooperation with those brands.

Terex jaw crusher liners codes

| SUPERTOOTH | QUARRY TOOTH | MULTI TOOTH | STANDARD TOOTH | HEAVY DUTY | ||

|---|---|---|---|---|---|---|

| J960 | ||||||

| Mn18 | Fixed jaw plate | 600/8048E | N.A | 600/8039E | 600/8011E | N.A |

| Swing jaw plate | 600/8049E | N.A | 600/8040E | 600/8012E | N.A | |

| Mn22 | Fixed jaw plate | 600/8048TT | N.A | N.A | N.A | N.A |

| Swing jaw plate | 600/8049TT | N.A | N.A | N.A | N.A | |

| Wedges | Fixed jaw plate | 600/8056 | N.A | 600/8058E | 600/8021M | N.A |

| Swing jaw plate | 600/8057 | N.A | 600/8059E | 600/8022M | N.A | |

| J1160 up to TRX1160JAOMHB5652 | ||||||

| Mn18 | Fixed jaw plate | 31.09.0100 | 31.09.0102 | 31.09.0103 | N.A | N.A |

| Swing jaw plate | 31.09.0101 | 31.09.0104 | 31.09.0105 | N.A | N.A | |

| Mn22 | Fixed jaw plate | N.A | 31.09.0107 | N.A | N.A | N.A |

| Swing jaw plate | N.A | 31.09.0109 | N.A | N.A | N.A | |

| J1160 RE-VAMP from TRX1161JEOMH95090 | ||||||

| Mn18 | Fixed jaw plate | CW017-002-MN180 | CW017-004-MN180 | CW017-006-MN180 | N.A | N.A |

| Swing jaw plate | CW017-001-MN180 | CW017-003-MN180 | CW017-005-MN180 | N.A | N.A | |

| Mn22 | Fixed jaw plate | CW017-002-MN220 | CW017-004-MN220 | N.A | N.A | N.A |

| Swing jaw plate | CW017-001-MN220 | CW017-003-MN220 | N.A | N.A | N.A | |

| J1170 | ||||||

| Mn18 | Fixed jaw plate | CR005-068-001E | CR005-143-001E | CR005-072-001E | CR005-008-001E | CW005-167-MN180 |

| Swing jaw plate | CR005-067-001E | CR005-141-001E | CR005-071-001E | CR005-007-001E | N.A | |

| Mn22 | Fixed jaw plate | CR005-068-001TT | N.A | CR005-072-001TT | CR005-008-001TT | CW005-167-MN220 |

| Swing jaw plate | CR005-067-001TT | N.A | CR005-071-001TT | CR005-007-001TT | N.A | |

| Mn14 | Fixed jaw plate | CR005-068-001M | N.A | CR005-072-001M | CR005-008-001M | N.A |

| Swing jaw plate | CR005-067-001M | N.A | CR005-071-001M | CR005-007-001M | N.A | |

| Wedges | Fixed jaw plate | CR005-070-001 | CR005-144-001 – RH | CR005-074-001 | CR005-010-001 | N.A |

| CR005-145-001- LH | ||||||

| Swing jaw plate | CR005-069-001 | CR005-142-001 | CR005-073-001 | CR005-009-001 | N.A | |

| J1175 | ||||||

| Mn18 | Fixed jaw plate | 31.10.1174 | 31.10.0205 | 31.10.1171 | N.A | CW024-001-MN180 |

| Old Part | Swing jaw plate | 31.10.1173 | 31.10.0210 | 31.10.1170 | N.A | N.A |

| Numbers | ||||||

| Mn18 | Fixed jaw plate | CW024-003-MN180 | CW024-006-MN180 | CW024-005-MN180 | N.A | CW024-001-MN180 |

| New Part | Swing jaw plate | CW024-002-MN180 | CW024-007-MN180 | CW024-004-MN180 | N.A | N.A |

| Numbers | ||||||

| Mn22 | Fixed jaw plate | 31.10.1181 | 31.10.0207 | N.A | N.A | CW024-001-MN220 |

| Old Part | Swing jaw plate | 31.10.1179 | 31.10.0212 | N.A | N.A | N.A |

| Numbers | ||||||

| Mn22 | Fixed jaw plate | CW024-003-MN220 | CW024-006-MN220 | N.A | N.A | CW024-001-MN220 |

| New Part | Swing jaw plate | CW024-002-MN220 | CW024-007-MN220 | N.A | N.A | N.A |

| Numbers | ||||||

| J1480 | ||||||

| Mn18 | Fixed jaw plate | 31.07.0136 | 31.07.0006 | N.A | N.A | CW020-001-MN180 |

| Swing jaw plate | CR020-017-001-E | CR020-044-001-E | N.A | N.A | N.A | |

| Mn22 | Fixed jaw plate | 31.07.2136 | 31.07.0007 | N.A | N.A | CW020-001-MN220 |

| Swing jaw plate | CR020-017-001TT | CR020-044-001TT | N.A | N.A | N.A |

Sandvik jaw crusher liners codes

| CORRUGATED | WIDE TEETH | WIDE WAVE | SHARP TEETH | COARSE CORRUGATED | HEAVY DUTY | HD ULTRA-THICK | ||

|---|---|---|---|---|---|---|---|---|

| CJ211 (J11) | ||||||||

| Mn14 | Fixed jaw plate | 400.2207-001 | N.A | N.A | 400.0739-001 | N.A | 400.2870-001 | N.A |

| Swing jaw plate | 400.1101-001 | N.A | N.A | 400.0738-001 | N.A | 400.2869-001 | N.A | |

| Mn18 | Fixed jaw plate | 400.2207-002 | N.A | N.A | 400.0739-002 | N.A | 400.2870-002 | N.A |

| Swing jaw plate | 400.2207-002 | N.A | N.A | 400.0738-002 | N.A | 400.2869-001 | N.A | |

| Upper plate | 400.0639-001 | |||||||

| CJ409 (JM907) | ||||||||

| Mn14 | Fixed jaw plate | 400.0418-001 | 400.0483-001 | N.A | N.A | N.A | N.A | N.A |

| Swing jaw plate | 400.0417-001 | 400.0483-001 | N.A | N.A | N.A | N.A | N.A | |

| Mn18 | Fixed jaw plate | 400.0418-002 | 400.0483-002 | N.A | N.A | N.A | N.A | N.A |

| Swing jaw plate | 400.0417-002 | 400.0483-002 | N.A | N.A | N.A | N.A | N.A | |

| Upper plate | 10-314-386-000 | |||||||

| Lower plate | 10-314-404-000 | |||||||

| CJ411 (JM1108) | ||||||||

| Mn14 | Fixed jaw plate | 400.0409-001 | 400.0436-001 | N.A | N.A | 400.0437-001 | N.A | N.A |

| Swing jaw plate | 400.0410-001 | 400.0436-001 | N.A | N.A | 400.0433-001 | N.A | N.A | |

| Mn18 | Fixed jaw plate | 400.0409-002 | 400.0436-002 | N.A | N.A | 400.0437-002 | N.A | N.A |

| Swing jaw plate | 400.0410-002 | 400.0436-002 | N.A | N.A | 400.0433-002 | N.A | N.A | |

| Upper plate | 10-314-262-000 | |||||||

| Lower plate | 10-314-262-000 | |||||||

| CJ412 (JM1208) | ||||||||

| Mn14 | Fixed jaw plate | 400.0407-001 | 400.0411-001 | N.A | 402.4744-01 | 400.0425-001 | 400.0413-001 | 400.0413-001 |

| Swing jaw plate | 400.0408-001 | 400.0411-001 | N.A | 402.4745-01 | 400.0420-001 | 400.0412-001 | 400.0420-001 | |

| Mn18 | Fixed jaw plate | 400.0407-002 | 400.0411-002 | N.A | 402.4744-02 | 400.0425-002 | 400.0413-002 | 400.0413-002 |

| Swing jaw plate | 400.0408-002 | 400.0411-002 | N.A | 402.4745-02 | 400.0420-002 | 400.0412-002 | 400.0420-002 | |

| Upper plate | 10-314-262-000 | |||||||

| Lower plate | 10-314-263-000 | |||||||

| CJ612 (JM1211) | ||||||||

| Mn14 | Fixed jaw plate | N.A | N.A | 400.0440-001 | 402.4747-01 | 400.2266-001 | 400.0426-001 | 400.0426-001 |

| Fixed middle jaw plate | N.A | N.A | 400.0442-001 | N.A | N.A | 400.0427-001 | 400.0427-001 | |

| Swing jaw plate | N.A | N.A | 400.0438-001 | 402.4748-01 | 400.0443-001 | 400.0423-001 | 400.0443 -001 | |

| Swing middle jaw plate | N.A | N.A | 400.0439-001 | N.A | N.A | 400.0424-001 | N.A | |

| Mn18 | Fixed jaw plate | N.A | N.A | 400.0440-002 | 402.4747-02 | 400.2266-002 | 400.0426-002 | 400.0426-002 |

| Fixed middle jaw plate | N.A | N.A | 400.0442-002 | N.A | N.A | 400.0427-002 | 400.0427-002 | |

| Swing jaw plate | N.A | N.A | 400.0438-002 | 402.4748-02 | 400.0443-002 | 400.0423-002 | 400.0443 -002 | |

| Swing middle jaw plate | N.A | N.A | 400.0439-002 | N.A | N.A | 400.0424-002 | N.A | |

| Upper plate | 402.4239-01 | |||||||

| Lower plate | 402.4635-01 | |||||||

| CJ613 (JM1312) | ||||||||

| Mn14 | Fixed jaw plate | 400.0447-001 | N.A | N.A | 400.0963-001 | 400.0422-001 | N.A | BG00372142-01 |

| Swing jaw plate | 400.0446-001 | N.A | N.A | 400.0964-001 | 400.0421-001 | N.A | 400.0421-001 | |

| Mn18 | Fixed jaw plate | 400.0447-002 | N.A | N.A | N.A | 400.0422-002 | N.A | BG00372142-02 |

| Swing jaw plate | 400.0446-002 | N.A | N.A | N.A | 400.0421-002 | N.A | 400.0421-002 | |

| Mn22 | Fixed jaw plate | N.A | N.A | N.A | 400.0963-004 | N.A | N.A | N.A |

| Swing jaw plate | N.A | N.A | N.A | 400.0964-004 | N.A | N.A | N.A | |

| Upper plate | 10-214-351-000 | |||||||

| Lower plate | 10-214-352-000 | |||||||

| Upper plate (HX900) | BG00395192 | |||||||

| Lower plate (HX900 | BG00395193 | |||||||

| CJ615 (JM1511) | ||||||||

| Mn14 | Fixed jaw plate | N.A | N.A | N.A | 400.0490-001 | 400.0485-001 | 400.0434-001 | 400.0434-001 |

| Fixed middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0435-001 | 400.0435-001 | |

| Swing jaw plate | N.A | N.A | N.A | 400.0491-001 | 400.0488-001 | 400.0434-001 | 400.0488-001 | |

| Swing middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0435-001 | N.A | |

| Mn18 | Fixed jaw plate | N.A | N.A | N.A | N.A | 400.0485-002 | 400.0434-002 | N.A |

| Fixed middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0435-002 | N.A | |

| Swing jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0434-002 | N.A | |

| Swing middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0435-002 | N.A | |

| Mn22 | Fixed jaw plate | N.A | N.A | N.A | 400.0490-004 | 400.0485-004 | 400.0434-004 | 400.0434-004 |

| Fixed middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0435-004 | 400.0435-004 | |

| Swing jaw plate | N.A | N.A | N.A | 400.0491-004 | 400.0488-004 | 400.0434-004 | 400.0488-004 | |

| Swing middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0435-004 | N.A | |

| Upper plate | 402.4521-01 | |||||||

| Lower plate | 402.4522-01 | |||||||

| CJ815 (JM1513) | ||||||||

| Mn14 | Fixed jaw plate | N.A | N.A | N.A | 400.0780-001 | 400.0473-001 | 400.0463-001 | 400.0463-001 |

| Fixed middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0462-001 | 400.0462-001 | |

| Swing jaw plate | N.A | N.A | N.A | 400.0779-001 | 400.0472-001 | 400.0460-001 | 400.0472-001 | |

| Swing middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0461-001 | N.A | |

| Mn18 | Fixed jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0463-002 | N.A |

| Fixed middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0462-001 | N.A | |

| Swing jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0460-001 | N.A | |

| Swing middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0461-001 | N.A | |

| Mn22 | Fixed jaw plate | N.A | N.A | N.A | 400.0780-004 | 400.0473-004 | 400.0463-004 | 400.0463-004 |

| Fixed middle jaw plate | N.A | N.A | N.A | N.A | N.A | 400.0460-004 | 400.0462-004 | |

| Swing jaw plate | N.A | N.A | N.A | 400.0779-004 | 400.0472-004 | 400.0461-004 | 400.0472-004 | |

| Swing middle jaw plate | N.A | N.A | N.A | N.A | N.A | N.A | N.A | |

| Upper plate | 402.4361-01 | |||||||

| Lower plate | 402.4622-01 |

Metso jaw crusher liners codes

| Metso jaw crusher liners codes | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quarry | Super grip + Quarry | Superteeth | MX | Standard | Special | |||||||

| Type | Movable jaws | Fixed jaws | Movable jaws | Fixed jaws | Movable jaws | Fixed jaws | Movable jaws | Fixed jaws | Movable jaws | Fixed jaws | Movable jaws | Fixed jaws |

| C110 | N11918208 | 814391312500 | MM0534103 | 814391312500 | 1046590661 | 1046590660 | MM0376278 | MM0376280 | 814390435200 | 814390435100 | 814329539800 | 814329539700 |

| C120 | MM0586425 | MM0585542 | MM0588282 | MM0585542 | MM0588450 | MM0588449 | MM1103860 | MM1103600 | 814328561400 | 814328501200 | 814320042700 | 814320042000 |

| C125 | N11954353 | N11954343 | MM0285590 | N11954343 | 1046590663 | 1046590664 | MM1031938 | MM1031747 | ||||

| C130 | MM1031742 | MM1086204 | MM1071843 | MM1086204 | ||||||||

| C140 | MM0218048 | MM0218047 | MM0404574 | MM0218047 | MM1122242 | MM1122241 | 814328598900 | 814328598800 | ||||

| C145 | MM0226278 | MM0226277 | MM0226707 | MM0226277 | 814390552700 | 814390552600 | ||||||

| C150 | MM1110178 | MM1004104 | MM1011873 | MM1004104 | ||||||||

| C160 | N11924296 | N11924295 | MM0219198 | N11924295 | N11953473 | N11953466 | 814329274900 | 814329275000 | ||||

| 814329291500 | 814390844600 | |||||||||||

| C100 | 814320042200 | 814320042100 | 814346591200 | 814346590860 | 814320037400 | 814320037300 | ||||||

| C105 | 814391378000 | 814391359800 | N11928919 | N11928918 | ||||||||

| C106 | MM0273926 | MM0273925 | MM0268263 | MM0268262 | MM0273924 | MM0273923 | MM03101730 | MM0301729 | ||||

| C3054 | N11952744 | N11952743 | MM0257640 | MM0274303 | MM0274302 | MM0247232 | MM0247231 | |||||

| C63 | 814320042500 | 814320042600 | 814329297800 | 814329297700 | ||||||||

| C80 | 814390736700 | N11921412 | N11921411 | 814390305400 | 814390305300 | |||||||

| C96 | N11948450 | N11942233 | MM0236248 | MM0215712 | N11934485 | N11948449 | MM0208851 | MM0260417 |

Cone crusher wear parts

Cone crusher wear parts include:

- Cone crusher mantle, which covers the cone head of the crusher to protect it from wear. It is the inner sacrificial wear liner that sits on the cone head.

- Cone crusher concave, which sits in the upper frame of the crusher to protect it from wear. It is the outer sacrificial wear liner that sits inside the upper frame.

- Torch ring. The lock nut and the mantle are transferred and sealed by the welding torch ring. At the same time, the torch ring is also used as the destruction body when the movable cone lock nut is removed.

Cone crusher liners selection

A wide range of liners are available to accommodate coarse and fine feeds, but which you choose depends on several factors.

- Feed sizes. The most important factor in Cone Crusher liner selection is the feed. You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally considered as 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two; 40-60% passing the midpoint; 0-10% passing the closed-side setting. You want to match the entire feed gradation, not just the feed size so that you utilize the entire chamber. It is important to utilize as much of the crushing chamber as possible to get the required reduction and desired throughput. Plant feed size and the output from your previous crushing stage define your top feed size, which will give the maximum cavity opening. The cavity opening should not be too big in relation to the top feed size. Cavity openings that are much larger than the feed size leads to poorly utilized reduction and liners. If the feed size is too small, the majority of the crushing takes place in the lowest portion of the cavity, which means the bottom of the liners will wear away faster than the top of the liners. The production will decrease due to the poor reduction ratio. The power limit of the crusher will be exceeded at a minimal volume level, and you’ll run the risk of improper bearing alignment. Most of the wear on crusher liners occurs right before the parallel zone (the smallest space between the mantle and the concaves where the final crushing takes place), but this wear will be accentuated if the feed is too small, and you’ll end up with a bowled-out pocket before the parallel zone way too soon. On the other hand, if the feed size is too coarse, the feed material will keep percolating around the feed opening, causing the top of the liners to wear away faster. Because the feed opening is bridged over, throughput is reduced and production decreases. The output gradation will be coarser, and the product will be slabby, not cubical. The volume limit will be exceeded at a minimal power draw. Understanding your gradation going into the crusher helps you to choose the right liner configuration necessary to achieve your production goals. The right liner selection gives you a better nip and more room to adjust other parameters, such as a closed-side setting.

- Feed grading. The maximum feed size is important as if there are a lot of fines in the feed or a lot of single sizes in the feed, it can cause issues with wear and output. Attention should also be given to recirculating stone for the following reasons: It has a tendency to be a lot more abrasive and harder than virgin stone; Depending on the amount recirculating, it can cause issues with the segregated feed.

- Output required. This takes into account output and grading required, which can affect which crushing chamber you should select.

Cone crusher liners cavity selection

Different brands of cone crushers, different cone crusher liners cavity types. There are some famous brands of cone crusher liners cavity types:

- Metso cone crusher liners cavity

- Sandvik cone crusher liners cavity

- Terex cone crusher liners cavity

Metso cone crusher liners cavity

Sandvik cone crusher liners cavity

- Extra coarse cavity

- Coarse cavity

- Medium coarse cavity

- Medium cavity

- Medium fine cavity

- Fine cavity

- Extra fine cavity

Terex cone crusher liners cavity

- Medium coarse cavity

- Coarse cavity

- Extra coarse cavity

- Fine cavity

- Auto sand cavity

- Heavy-duty cavity

Cone crusher liners codes

There are some famous cone crusher liners codes. It does not mean that Qiming Machinery has any cooperation with those brands.

Terex cone crusher liners codes

| Terex cone crusher liners codes | Medium Coarse | Coarse | Extra Coarse | Fine | Auto Sand | Heavy Duty | |

|---|---|---|---|---|---|---|---|

| C1540 Cone Crusher Liners | |||||||

| Mn18 | Mantle | 31.12.0252 | 31.12.0252 | 31.12.0252 | 31.12.0252 | 603/9273E | |

| Concave | 31.12.0316 | 31.12.0315 | 603/9053E | 31.12.0317 | 603/9274E | ||

| Mn22 | Mantle | 31.12.0355 | 31.12.0355 | 31.12.0355 | 603/9273TT | ||

| Concave | 31.12.0358 | 603/9053TT | 603/9071TT | 603/9274TT | |||

| C1545 Cone Crusher Liners | |||||||

| Mn18 | Mantle | CW023-006-MN180 | CW023-006-MN180 | CW023-006-MN180 | CW023-007-MN180 | ||

| Concave | CW023-003-MN180 | CW023-005-MN180 | CW023-002-MN180 | CW023-008-MN180 | |||

| Mn22 | Mantle | CW023-006-MN220 | CW023-006-MN220 | CW023-006-MN220 | CW023-007-MN220 | ||

| Concave | CW023-003-MN220 | CW023-005-MN220 | CW023-002-MN220 | CW023-008-MN220 | |||

| C1550 Cone Crusher Liners | |||||||

| Mn18 | Mantle | 603/1508E | 603/1508E | 603/1617E | |||

| Concave | 603/1416E | 603/1407E | 603/1618E | ||||

| Mn22 | Mantle | 603/1508TT | 603/1508TT | 603/1617TT | |||

| Concave | 603/1416TT | 603/1407TT | 603/1618TT | ||||

| C1554 Cone Crusher Liners | |||||||

| Mn18 | Mantle | 054003002001E | 054003002001E | 054003002001E | 054003002001E | 054003002001E | |

| Concave | 0540030015E | 0540030016E | 0540030018E | 0540030018E | 0540030019E | ||

| Mn22 | Mantle | 054003002001TT | 054003002001TT | 054003002001TT | |||

| Concave | 0540030015TT | 0540030016TT | 0540030017TT |

Metso cone crusher liners codes

| Metso Cone Crusher Liners Codes | ||

|---|---|---|

| GP100 Cone Crusher Liners | ||

| Mantle | Concave | |

| Coarse | 814328537800 MM0309236 | 814328537700 N11950658 |

| Fine | 814328537800 MM0309236 | 814317183600 |

| Medium | 814328537800 MM0309236 | 814318865500 |

| Medium Fine | 814328537800 MM0309236 | 814317178300 |

| Extra Fine | 814390490400 | 814329529300 |

| GP100S Cone Crusher Liners | ||

| Coarse | 814317177900 | 814328570600 814329234600 |

| Medium | 814317177900 | 814328546200 814328546300 |

| GP11F Cone Crusher Liners | ||

| Coarse | 814320044100 | 814328546000 |

| Fine | 814317169500 | 814317171900 N11950666 |

| Medium | 814320044100 | 814317177700 814390827200 |

| Extra Fine | 814317169500 | 814317169600 N11950666 |

| GP11M Cone Crusher Liners | ||

| Coarse | 814318675800 | |

| Extra Coarse | 814318848600 | 814318848700 814390523400 |

| GP200 Cone Crusher Liners | ||

| Extra Coarse | N11933947 | N11944215 |

| Fine | N11933947 | N11933948 N11944214 |

| Medium | N11933947 | N11933949 |

| Extra Fine | N11942003 | N11942004 |

| Medium Coarse | N11951220 | |

| GP200S Cone Crusher Liners | ||

| Coarse | 814390727700 | 814391704400 814391704500 |

| Extra Coarse | 814390727700 | 814390727800 814390727900 |

| GP220 Cone Crusher Liners | ||

| Coarse | MM0528576 | MM0528578 |

| GP300 Cone Crusher Liners | ||

| Coarse | MM0242240 | N11905094 N11920194 N11920196 |

| Extra Coarse | MM0242240 | MM0242241 N11920196 N11920197 |

| Medium | N11920192 | N11920195 |

| Medium Fine | N11920192 | N11905094 N11920194 |

| GP300S Cone Crusher Liners | ||

| Coarse | 814318836900 | 814318862000 814318862100 |

| Extra Coarse | 814318836900 814390336100 | 814329276100 814329276200 814390336200 |

| GP500 Cone Crusher Liners | ||

| Medium Fine | 814318607800 N11922661 N11922662 | 814318921300 N11922731 |

| GP500S Cone Crusher Liners | ||

| Coarse | 814329548400 N11941327 | N11941326 |

| Extra Coarse | 814390882100 814390882200 N11941328 N11947962 | N11941328 N11947963 |

| GP550 Cone Crusher Liners | ||

| Coarse | N11951712 | |

| Extra Coarse | N11951712 | N11951717 |

| Fine | N11951712 | |

| Medium | N11951712 | N11951715 |

| Medium Fine | N11951712 | |

| HP100 Cone Crusher Liners | ||

| Coarse | 7055308121 | 7055208002 MM0544964 |

| Extra Coarse | 7055308121 | 7055208003 |

| Fine | 7055308122 | 7055208001 |

| Medium | 7055308121 | 7055208001 MM0545036 |

| Extra Fine | 7055308122 N55308129 | 7055208000 N55208010 |

| Medium Coarse | 7055308121 | |

| HP200 Cone Crusher Liners | ||

| Coarse | 1050130813 STD 1050130815 SH N55308011 STD N55308012 SH | N55208135 STD N55208144 SH |

| Fine | 1050130813 STD 1050130815 SH N55308011 STD N55308012 SH | N55208140 STD N55208141 STD N55208150 SH |

| Medium | 1050130813 STD 1050130815 SH N55308011 STD N55308012 SH | N55208137 STD N55208138 STD N55208146 SH N55208147 SH |

| Extra Fine | N55208153 SH | |

| HP300 Cone Crusher Liners | ||

| Coarse | N55308261 SH/STD N55308267 SH/STD | 1048294342 SH 1048294639 STD N55208262 SH N55208267 STD N55208280 STD N55208283 SH |

| Extra Coarse | N55308265 STD | N55208266 STD N55208279 STD |

| Fine | N55308261 SH/STD N55308267 SH/STD | N55208269 STD N55208282 STD N55208285 SH |

| Medium | N55308261 SH/STD N55308267 SH/STD | 1048294340 SH N55208268 STD N55208281 STD N55208284 SH |

| Extra Fine | N55308260 SH N55308266 SH | N55208286 SH |

| HP4 Cone Crusher Liners | ||

| Coarse | N55309259 | |

| Extra Coarse | N55309259 | N55209254 |

| Fine | N55309257 | N55209252 |

| Medium | N55309258 | N55209253 |

| Extra Fine | N55309256 | N55209255 |

| HP400 Cone Crusher Liners | ||

| Coarse | 7055308282 SH 7055308388 SH N55308511 STD N55308512 STD | 1048300031 SH 1048300039 SH N55208398 STD N55208399 STD N55208522 STD |

| Extra Coarse | N55308511 STD N55308512 STD | N55208523 STD |

| Fine | 7055308282 SH 7055308381 STD 7055308387 STD 7055308388 SH | 7055208382 STD 7055208392 STD 7055208395 SH |

| Medium | 7055308282 SH 7055308388 SH N55308511 STD N55308512 STD | 1048300032 SH 1048300035 SH N55208526 STD |

| Extra Fine | 7055308389 SH | 1048300043 SH |

| HP5 Cone Crusher Liners | ||

| Coarse | N55309501 | |

| Extra Coarse | N55309500 | N55209501 |

| Fine | N55309502 | N55209504 |

| Medium | N55309501 | N55209503 |

| Extra Fine | N55309502 | |

| HP500 Cone Crusher Liners | ||

| Coarse | N55308514 STD N55308515 STD N55308516 STD N55308520 SH | 1048314236 STD 1048314241 SH 1048314243 STD 7055208514 STD N55208532 SH |

| Extra Coarse | N55308514 STD N55308515 STD N55308516 STD N55308520 SH | 1048314240 STD 1048314244 STD |

| Fine | 7055308501 STD 7055308503 STD 7055308508 STD 7055308509 SH | 7055208502 STD 7055208516 STD 7055208519 SH |

| Medium | 7055308501 STD 7055308503 STD 7055308508 STD 7055308509 SH N55208528 SH | 1048314242 SH 7055208512 STD 7055208515 STD |

| Extra Fine | 7055308510 SH | 7055208520 SH |

| HP700 Cone Crusher Liners | ||

| Coarse | 1050143833 | 1050143842 |

| Fine | MM0341717 SH | MM0341718 SH |

| Medium | 1050143800 1050143829 1050143833 MM0335582 SH | 1048314310 SH 1048314349 SH |

| HP800 Cone Crusher Liners | ||

| Coarse | 1050143849 STD | 1048314344 |

| Fine | 1050143852 SH | |

| Medium | 1050143810 SH 1050143852 SH | 1048314364 SH |

| MP800 Cone Crusher Liners | ||

| Coarse | 1050143900 STD 1050143950 SH | |

| Fine | 1048315250 SH | |

| Medium | 1050143953 SH | 1048315201 STD 1048315255 SH |

| Notice: SH means Short Head, STD means Standard |

Sandvik cone crusher liners codes

| Sandvik Cone Crusher Liners Codes | |||||

|---|---|---|---|---|---|

| CS420 (S2800) Cone Crusher Liners | |||||

| Material | |||||

| Concave | Mn14 | Mn18 | Mn22 | ||

| Extra Coarse Upper | 442.8550-00 | 442.8550-90 | / | ||

| Extra Coarse Lower | 442.8464-00 | 442.8464-90 | / | ||

| Coarse Upper | 442.7379-00 | 442.7379-90 | / | ||

| Coarse Lower | 442.8522-00 | 442.8522-90 | 442.8522-91 | ||

| Mantle | |||||

| A | 442.9288-01 | 442.9288-02 | / | ||

| B | 442.6789-01 | 442.6789-02 | 442.6789-03 | ||

| CS430 (S3800) Cone Crusher Liners | |||||

| Concave | Mn14 | Mn18 | Mn22 | ||

| Extra Coarse Cavity (Semi-metallic backing) | |||||

| Extra Coarse Upper | 442.8484-00 | 442.8484-90 | 442.8484-91 | ||

| Extra Coarse Lower | 452.7001-901 | 452.7001-902 | 452.7001-903 | ||

| Extra Coarse Second Lower | BG00174250 | BG00174251 | BG00174252 | ||

| Extra Coarse Cavity (Non-metallic backing) | |||||

| Extra Coarse Upper | 442.8484-00 | 442.8484-90 | 442.8484-91 | ||

| Extra Coarse Lower | 442.8477-00 | 442.8477-90 | 442.8477-91 | ||

| Extra Coarse Second Lower | 452.1952-901 | 452.1952-902 | 452.1952-903 | ||

| Coarse Cavity (Semi-metallic backing) | |||||

| Coarse Upper | 442.8485-00 | 442.8485-90 | 442.8485-91 | ||

| Coarse Lower | 452.7002-901 | 452.7002-902 | 452.7002-903 | ||

| Coarse Second Lower | BG00174521 | BG00174693 | BG00174694 | ||

| Coarse Cavity (Non-metallic backing) | |||||

| Coarse Upper | 442.8485-00 | 442.8485-90 | 442.8485-91 | ||

| Coarse Lower | 442.8478-00 | 442.8478-90 | 442.8478-91 | ||

| Coarse Second Lower | 452.1954-901 | 452.1954-902 | 452.1954-903 | ||

| Mantle | |||||

| A | 442.8470-01 | 442.8470-02 | 442.8470-03 | ||

| B | 442.8471-01 | 442.8471-02 | 442.8471-03 | ||

| CS440 (S4800) Cone Crusher Liners | |||||

| Concave | Mn14 | Mn18 | Mn22 | ||

| Extra Coarse Cavity (Semi-metallic backing) | |||||

| Extra Coarse Upper | 442.8115-00 | 442.8115-90 | 442.8115-91 | ||

| Extra Coarse Lower | 452.6264-901 | 452.6264-902 | 452.6264-903 | ||

| Extra Coarse Cavity (Non-metallic backing) | |||||

| Extra Coarse Upper | 442.8115-00 | 442.8115-90 | 442.8115-91 | ||

| Extra Coarse Lower | 442.8114-00 | 442.8114-90 | 442.8114-91 | ||

| Extra Coarse Second Lower | 452.1955-901 | 452.1955-902 | 452.1955-903 | ||

| Extra Coarse Coarse Lower | 452.1544-001 | 452.1544-002 | 452.1544-003 | ||

| Coarse Cavity (Semi-metallic backing) | |||||

| Coarse Upper | 442.8099-00 | 442.8099-90 | 442.8099-91 | ||

| Coarse Lower | 452.3821-901 | 452.3821-902 | 452.3821-903 | ||

| Coarse Cavity (Non-metallic backing) | |||||

| Coarse Upper | 442.8099-00 | 442.8099-90 | 442.8099-91 | ||

| Coarse Lower | 442.8098-00 | 442.8098-90 | 442.8098-91 | ||

| Coarse Second Lower | 452.0945-901 | 452.0945-902 | 452.0945-903 | ||

| Medium Coarse Cavity (Semi-metallic backing) | |||||

| Upper | 452.0474-901 | 452.0474-902 | 452.0474-903 | ||

| Lower | 452.6265-901 | 452.6265-902 | 452.6265-903 | ||

| Medium Coarse Cavity (Non-metallic backing) | |||||

| Upper | 452.0474-901 | 452.0474-902 | 452.0474-903 | ||

| Lower | 452.0273-901 | 452.0273-902 | 452.0273-903 | ||

| Second Lower | 452.1972-901 | 452.1972-902 | 452.1972-903 | ||

| Mantle | |||||

| A | 442.8089-01 | 442.8089-02 | 442.8089-03 | ||

| S | 452.0943-001 | 452.0943-002 | 452.0943-003 | ||

| B | 442.8070-01 | 442.8070-02 | 442.8070-03 | ||

| BC | 452.1545-001 | 452.1545-002 | 452.1545-003 | ||

| CS550 Cone Crusher Liners | |||||

| Concave | Mn14 | Mn18 | Mn22 | ||

| Extra Coarse Upper | 670.4004-001 | 670.4004-002 | 670.4004-003 | ||

| Extra Coarse Lower | 670.4003-001 | 670.4003-002 | 670.4003-003 | ||

| Coarse Upper | 670.4007-001 | 670.4007-002 | 670.4007-003 | ||

| Coarse Lower | 670.4006-001 | 670.4006-002 | 670.4006-003 | ||

| Mantle | |||||

| A | 452.9000-001 | 452.9000-002 | 452.9000-003 | ||

| S | 452.9002-001 | 452.9002-002 | 452.9002-003 | ||

| B | 452.9001-001 | 452.9001-002 | 452.9001-003 | ||

| CS660(S6800) Cone Crusher Liners | |||||

| Concave | Mn14 | Mn18 | Mn22 | ||

| Extra Coarse Cavity (Semi-metallic backing) | |||||

| Extra Coarse Upper | 442.8981-00 | 442.8981-90 | 442.8981-91 | ||

| Extra Coarse Lower | 452.5920-901 | 452.5920-902 | 452.5920-903 | ||

| Extra Coarse Cavity (Non-metallic backing) | |||||

| Extra Coarse Upper | 442.8981-00 | 442.8981-90 | |||

| Extra Coarse Lower | 442.8979-00 | 442.8979-90 | |||

| Coarse Cavity (Semi-metallic backing) | |||||

| Coarse Upper | 442.9072-00 | 442.9072-00 | |||

| Coarse Lower | 452.3822-901 | 452.3822-902 | |||

| Coarse Cavity (Non-metallic backing) | |||||

| Coarse Upper | 442.9072-00 | 442.9072-90 | |||

| Coarse Lower | 442.9071-00 | 442.9071-90 | |||

| Coarse Second Lower | BG0122422-01 | BG01221422-02 | |||

| Medium Coarse Cavity (Semi-metallic backing) | |||||

| Upper | 452.9040-901 | 452.9040-902 | |||

| Lower | 452.9041-901 | 452.9041-902 | |||

| Mantle | |||||

| A | 442.8982-01 | 442.8982-02 | |||

| B | 442.8983-01 | 442.8983-02 | |||

| CH420 Cone Crusher Liners | |||||

| Concave | Mn14 | Mn18 | Mn22 | ||

| Extra Coarse Cavity | 442.9569-01 | 442.9569-02 | 442.9569-03 | ||

| Coarse Cavity | 442.9587-01 | 442.9587-02 | 442.9587-03 | ||

| Medium Cavity | 442.9586-01 | 442.9586-02 | 442.9586-03 | ||

| Medium Fine Cavity | 442.9584-01 | 442.9584-02 | 442.9584-03 | ||

| Extra Fine Cavity | 442.9583-01 | 442.9583-02 | 442.9583-03 | ||

| Mantle | |||||

| Extra Coarse Cavity A | 442.9698-01 | 442.9698-02 | 442.9698-03 | ||

| Extra Coarse Cavity B | 442.6197-01 | 442.6197-02 | 442.6197-04 | ||

| Coarse Cavity A | 442.9698-01 | 442.9698-02 | 442.9698-03 | ||

| Coarse Cavity B | 442.6197-01 | 442.6197-02 | 442.6197-04 | ||

| Medium Cavity B | 442.6197-01 | 442.6197-02 | 442.6197-04 | ||

| Medium Cavity HC | 442.9761-01 | 442.9761-02 | 442.9761-03 | ||

| Medium Fine Cavity B | 442.6197-01 | 442.6197-02 | 442.6197-04 | ||

| Medium Fine Cavity HC | 442.9761-01 | 442.9761-02 | 442.9761-03 | ||

| Extra Fine Cavity A | 442.9698-01 | 442.9698-02 | 442.9698-03 | ||

| Extra Fine Cavity B | 442.6197-01 | 442.6197-02 | 442.6197-04 | ||

| Extra Fine Cavity HC | 442.9761-01 | 442.9761-02 | 442.9761-03 | ||

| Extra Fine Cavity EF | 442.7000-01 | 442.7000-02 | 442.7000-03 | ||

| H2000 Cone Crusher Liners | |||||

| Concave | Mn14 | Mn18 | Mn22 | ||

| Coarse Cavity | 442.6221-01 | 442.6221-02 | 442.6221-03 | ||

| Medium Coarse Cavity | 452.3044-001 | 452.3044-002 | 452.3044-003 | ||

| Medium Cavity | 442.6428-01 | 442.6428-02 | 442.6428-04 | ||

| Fine Cavity | 442.6580-01 | 442.6580-02 | |||

| Mantle | |||||

| Coarse Cavity B | 442.6197-01 | 442.6197-02 | 442.6197-04 | ||

| Medium Coarse Cavity B | 442.6197-01 | 442.6197-02 | 442.6197-04 | ||

| Medium Cavity B | 442.6197-01 | 442.6197-02 | 442.6197-04 | ||

| Fine Cavity B | 442.6197-01 | 442.6197-02 | |||

| Flexifeed | BG00143591-01 | BG00143591-02 | BG00143591-04 | ||

| CH430 (H3800) Cone Crusher Liners | |||||

| Mn14 | Mn18 | Mn22 | |||

| Concave | |||||

| Extra Coarse Cavity | 442.8249-01 | 442.8249-02 | 442.8249-03 | ||

| Coarse Cavity | 442.8248-01 | 442.8248-02 | 442.8248-03 | ||

| Medium Coarse Cavity | 442.8247-01 | 442.8247-02 | 442.8247-03 | ||

| Medium Cavity | 442.8246-01 | 442.8246-02 | 442.8246-03 | ||

| Medium Fine Cavity | 452.1216-01 | 452.1216-02 | 452.1216-03 | ||

| Fine Cavity | 442.8251-01 | 442.8251-02 | 442.8251-03 | ||

| Extra Fine Cavity | 442.8630-01 | 442.8630-02 | 442.8630-03 | ||

| Mantle | |||||

| A | 442.7988-01 | 442.7988-02 | 442.7988-03 | ||

| S | 452.1171-001 | 452.1711-002 | 452.1711-003 | ||

| B | 442.7989-01 | 442.7989-02 | 442.7989-03 | ||

| FF | 452.6115-01 | 452.6115-02 | 452.6115-03 | ||

| CH440 (H4800) Cone Crusher Liners | |||||

| Mn14 | Mn18 | Mn22 | |||

| Concave | |||||

| Extra Coarse Top Grip Cavity | 452.3027-001 | 452.3027-002 | 452.3027-003 | ||

| Coarse Cavity | 442.8421-01 | 442.8421-02 | 442.8421-03 | ||

| Medium Coarse Cavity | 442.8420-01 | 442.8420-02 | 442.8420-03 | ||

| Medium Cavity | 442.8419-01 | 442.8419-02 | 442.8419-03 | ||

| Medium Fine Cavity | 442.8418-01 | 442.8418-02 | 442.8418-03 | ||

| Fine Cavity | 442.8417-01 | 442.8417-02 | 442.8417-03 | ||

| Extra Fine Cavity | 442.8416-01 | 442.8416-02 | 442.8416-03 | ||

| Mantle | |||||

| A | 442.7225-01 | 442.7225-02 | 442.7224-03 | ||

| B | 442.7230-01 | 442.7230-02 | 442.7230-03 | ||

| HC | 442.9073-01 | 442.9073-02 | 442.9073-03 | ||

| FF (A) | 452.5271-001 | 452.5271-002 | 452.5271-003 | ||

| FF (B) | 452.6063-001 | 452.6063-002 | 452.60603-003 | ||

| CH540 Cone Crusher Liners | |||||

| Mn14 | Mn18 | Mn22 | |||

| Concave | |||||

| Extra Coarse Top Grip Cavity | 452.8358-001 | 452.8358-002 | 452.8358-003 | ||

| Coarse Cavity | 452.8512-001 | 452.8512-002 | 452.8512-003 | ||

| Medium Cavity | 452.8513-001 | 452.8513-002 | 452.8513-003 | ||

| Fine Cavity | 452.8339-001 | 452.8339-002 | 452.8339-003 | ||

| Extra Fine Cavity | 452.8511-001 | 452.8511-002 | 452.8511-003 | ||

| Mantle | |||||

| A | 452.8432-001 | 452.8432-002 | 452.8432-003 | ||

| B | 452.8338-001 | 452.8338-002 | 452.8338-003 | ||

| EF | 452.8510-001 | 452.8510-002 | 452.8510-003 | ||

| FF | 452.9030-001 | 452.9030-002 | 452.9030-003 | ||

| CH550 Cone Crusher Liners | |||||

| Mn14 | Mn18 | Mn22 | |||

| Concave | |||||

| Extra Coarse Top Grip Cavity | 452.7843-001 | 452.7843-002 | 452.7843-003 | ||

| Coarse Cavity | 452.8500-001 | 452.8500-002 | 452.8500-003 | ||

| Medium Coarse Cavity | 452.8496-001 | 452.8496-002 | 452.8496-003 | ||

| Medium Cavity | 452.8601-001 | 452.8601-002 | 452.8601-003 | ||

| Fine Cavity | 452.8600-001 | 452.8600-002 | 452.8600-003 | ||

| Mantle | |||||

| A | 452.7626-001 | 452.7626-002 | 452.7626-003 | ||

| B | 452.8602-001 | 452.8602-002 | 452.8602-003 | ||

| FF | BG001333846-01 | BG001333846-02 | BG001333846-03 | ||

| CH660 (H6800) Cone Crusher Liners | |||||

| Mn14 | Mn18 | Mn22 | |||

| Concave | |||||

| Extra Coarse Cavity | 442.8813-01 | 442.8813-02 | 442.8813-03 | ||

| CX Cavity | 442.9230-01 | 442.9230-02 | 442.9230-03 | ||

| Coarse Cavity | 442.8814-01 | 442.8814-02 | 442.8814-03 | ||

| Medium Coarse Cavity | 442.8815-01 | 442.8815-02 | 442.8815-03 | ||

| Medium Cavity | 442.8816-01 | 442.8816-02 | 442.8816-03 | ||

| Medium Fine Cavity | 442.8817-01 | 442.8817-02 | 442.8817-03 | ||

| Fine Cavity | 442.8818-01 | 442.8818-02 | 442.8818-03 | ||

| Extra Fine Cavity | 452.0832-001 | 452.0832-002 | 452.0832-003 | ||

| Heavy R | BG00417468-01 | BG00417468-02 | BG00417468-03 | ||

| Mantle | |||||

| A | 442.8819-01 | 442.8819-02 | 442.8819-03 | ||

| D | 442.8821-01 | 442.8821-02 | 442.8821-03 | ||

| B | 442.8820-01 | 442.8820-02 | 442.8820-03 | ||

| EF | 452.0820-001 | 452.0820-002 | 452.0820-003 | ||

| HC | 442.9760-01 | 442.9760-02 | 442.9760-03 | ||

| CH860I (CH860) Cone Crusher Liners | |||||

| Mn14 | Mn18 | Mn22 | |||

| Concave | |||||

| Extra Coarse Top Grip Cavity | 452.8231-001 | 452.8231-002 | 452.8231-003 | ||

| Coarse Cavity | 452.8238-001 | 452.8238-002 | 452.8238-003 | ||

| Medium Coarse Cavity | 452.8239-001 | 452.8239-002 | 452.8239-003 | ||

| Medium Cavity | 452.8240-001 | 452.8240-002 | 452.8240-003 | ||

| Mantle | |||||

| A | 452.8232-001 | 452.8232-002 | |||

| B | 452.8233-001 | 452.8233-002 | |||

| FF | 452.8243-001 | 452.8243-002 | |||

| CH865I (CH865) Cone Crusher Liners | |||||

| Mn14 | Mn18 | ||||

| Concave | |||||

| Fine Cavity | 452.8242-001 | 452.8142-002 | |||

| Extra Fine Cavity | 452.8235-001 | 452.8235-002 | |||

| HR Cavity | 452.8446-001 | 452.8446-002 | |||

| Mantle | |||||

| A | 452.8232-001 | 452.8232-002 | |||

| B | 452.8233-001 | 452.8233-002 | |||

| EF | 452.8236-001 | 452.8236-002 | |||

| OB | 452.8244-001 | 452.8244-002 | |||

| CH865I (CH865) Cone Crusher Liners | |||||

| Mn14 | Mn18 | Speical Material | |||

| Concave | |||||

| Extra Coarse Top Grip Cavity | BG00239713-01 | BG00239713-02 | BG00239713-05 | ||

| Coarse Cavity | 452.2255-001 | 452.2255-002 | 452.2255-005 | ||

| Medium Coarse Cavity | 452.2253-001 | 452.2253-002 | 452.2253-005 | ||

| Medium Cavity | 452.1754-001 | 452.1754-002 | 452.1754-005 | ||

| Medium Fine Cavity | 452.0842-001 | 452.0842-002 | 452.0842-005 | ||

| Fine Cavity | 452.0841-001 | 452.0841-002 | 452.0841-005 | ||

| Extra Fine Cavity | 452.0840-001 | 452.0840-002 | 452.0840-005 | ||

| HR Cavity | BG00401157-01 | BG00401157-02 | BG00401157-05 | ||

| Mantle | |||||

| A | 452.0837-001 | 452.0837-002 | 452.0837-005 | ||

| B | BG00692006-01 | BG00692006-02 | BG00692006-05 | ||

| EF | 452.0844-001 | 452.0844-002 | 452.0844-005 | ||

| OB | 452.4900-001 | 452.4900-002 | 452.4900-005 | ||

| CH890I (CH890, CH880,H8800) Cone Crusher Liners | |||||

| Mn14 | Mn18 | Speical Material | |||

| Concave | |||||

| Extra Coarse Cavity | 442.9336-01 | 442.9336-005 | |||

| Coarse Cavity | 442.9398-01 | 442.9398-005 | |||

| Medium Coarse Cavity | 442.9471-01 | 442.9471-005 | |||

| Medium Cavity | 442.9337-01 | 442.9337-005 | |||

| Medium Fine Cavity | 442.9312-01 | 442.9312-005 | |||

| Fine Cavity | 442.9471-01 | 442.9471-005 | |||

| Mantle | |||||

| A | 442.9314-01 | 442.9314-005 | |||

| B | 442.9339-01 | 442.9339-005 | |||

| EF | 452.0264-001 | 452.0264-005 | |||

| OB | 452.4051-001 | 452.4051-005 | |||

| HC | 442.9758-01 | 442.9758-05 | |||

| FF | BG00282784-01 | BG00282784-05 | |||

| CH895I (CH895, CH880,H8800) Cone Crusher Liners | |||||

| Mn14 | Mn18 | Speical Material | |||

| Concave | |||||

| Extra Fine X Cavity | 452.1067-001 | 452.1067-005 | |||

| Extra Fine Cavity | 452.0263-001 | 452.0263-005 | |||

| Extra Extra Fine Cavity | 452.0579-001 | 452.0579-005 | |||

| HR Cavity | BG00284338-01 | BG00284338-05 | |||

| Mantle | |||||

| A | 442.9314-01 | 442.9314-005 | |||

| B | 442.9758-01 | 442.9758-05 | |||

| EF | 452.0264-001 | 452.0264-005 | |||

| OB | 452.4051-001 | 452.4051-005 | |||

| HC | 442.9758-01 | 442.9758-05 |

Impact crusher wear parts

Impact crusher wear parts include the following parts:

- Blow bars. Wear parts inserted into the rotor which impact the rock to cause breakage. These can be replaced when they are worn down. There are two different options: 4 high blow bars; 2 high and 2 low blow bars. Some older design crushers had a 3 bar rotor.

- Apron liners. Liners that are generally fitted to the end of aprons (which are replaceable wear parts) to ensure the apron settings can be maintained.

- Side liners. Sometimes called frame liners, these are used on the inside of the impactor body to protect it from wear.

Material selection for blow bars

Different working conditions need to choose the suitable material crusher blow bars, which can protect impact crusher and prolong wear parts working life.

| Material | Applications | Feed Size | Tramp Iron | Life Comparison | Conclusion |

|---|---|---|---|---|---|

| Manganese | Primary | Large | YES | 1X | • Good for crushing soft material • Used in primary and recycling applications • Can accommodate large feed size • Can tolerate steel in feed • Used in primary & recycling applications |

| Martensitic Steel | Secondary/ Concrete | Medium | SOME | 1.2 - 1.5X | • Good for hardness and impact resistance • Used in primary and recycling applications • Can accommodate large feed size • Can tolerate steel in feed • Used in primary & recycling applications |

| Martensitic Ceramic | Secondary/ Concrete | Medium | SOME | 2.4 - 6X | • Martensitic bar that has a got a ceramic matrix running through the blow bar for extra wear life • Maintains impact resistance of martensitic bar • Increases wear life • Used in primary & recycling applications |

| Chrome | Secondary/ Asphalt | Well prepared small | NO | 2 - 4X | • High Wear resistance • Feed size needs controlled due to risk of breakages • Will not tolerate steel in feed • Available as Medium chrome and High chrome • Used in secondary , tertiary & asphalt applications (as long as no unbreakable in feed ) |

| Chrome Ceramic | Secondary/ Asphalt | Well prepared small | NO | 4 - 16X | • Chrome bar that has a got a ceramic matrix running through the blow bar for extra wear life • Feed size needs controlled due to risk of breakages • Will not tolerate steel in feed • Used in secondary , tertiary & asphalt applications (as long as no unbreakable in feed ) |

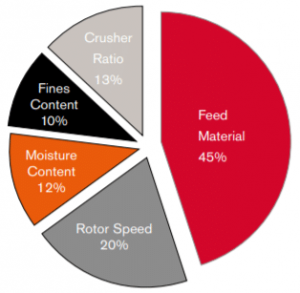

Influencing factors on blow bar wear

There are 5 factors on blow bar wear:

- Crusher ratio

- Fines content

- Moisture content

- Rotor speed

- Feed material

Feed material is the most important factor for selecting the correct blow bar. To increase the life of blow bars the following guidelines should be adhered to:

- Maintain and clean chamber daily.

- Inspect blow bars for premature wear or damage.

- Select correct blow bars depending on the application.

- Adjust machine parameters.

Notice: Qiming Machinery does not own or represent any of the brands stipulated here. Spare parts and components are completely interchangeable with parts of pointed equipment. Provided and produced with warranty obligations of the Qiming Machinery trademark. All designations, trademarks, and commercial names are mentioned on this site for informational purposes only and not for Qiming Machinery’s product differentiation.