Crush different kinds of stones or ores, it needs different jaw crusher tooth types to suit. There are some popular jaw plate tooth profiles and uses.

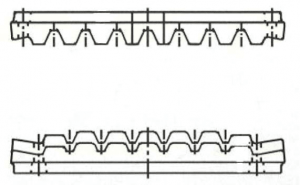

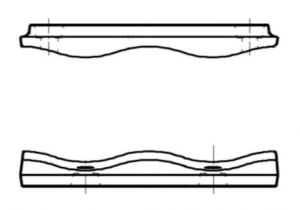

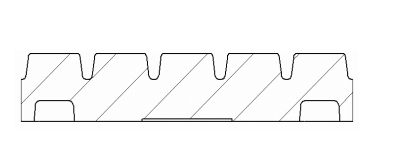

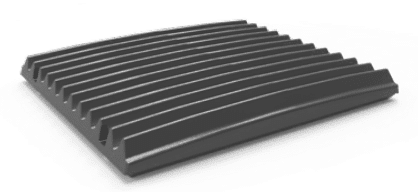

Tooth Profile: Standard Tooth

Uses: Suitable for both rock and gravel crushing; Wear life, power requirements, and crushing stresses in good balance; Typical factory installation.

Tooth Profile: Quarry Tooth

Uses: Suitable for crushing Shot Rock in quarries; The flat teeth perform better with abrasive materials; (more wearable tooth material); Causes higher stresses and increases power requirements.

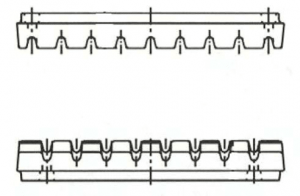

Tooth Profile: Super Tooth

Uses: Suitable for general use and especially a good choice for gravel crushing; Large mass and special design of the teeth gives long wear life and allows fine material flow down through the cavity along the grooves without wearing the teeth.

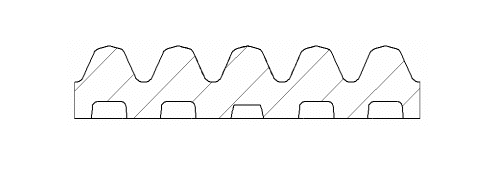

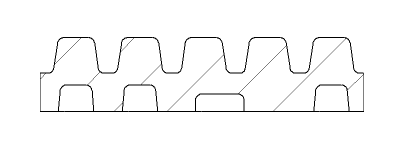

Tooth Profile: Corrugated Recycling Tooth

Uses: Suitable for crushing concrete; Fine material flows easily through the cavity along the large grooves.

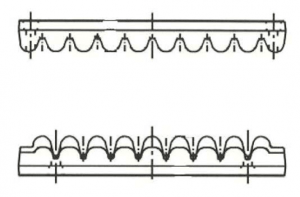

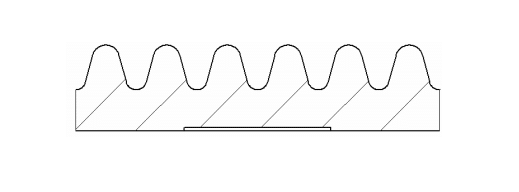

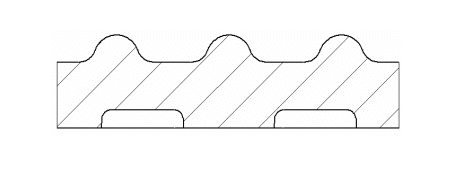

Tooth Profile: Wavy Recycling Tooth

Uses: Suitable for crushing Asphalt, Material flows easily down through the cavity along the grooves without packing; Normally used in the small setting range with the intermediate plate.

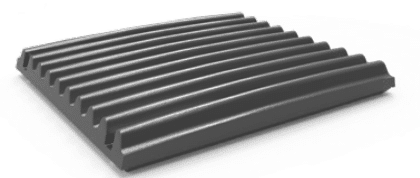

Tooth Profile: Super Grip Tooth

Uses: Suitable for hard and round natural rock crushing; Provides better grip and capacity; Fine material flows easily through the cavity along the large grooves; Wear life of the fixed and movable jaw dies in good balance.

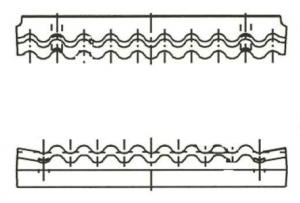

Tooth Profile: Wedge & Standard Tooth

Uses: Suitable for both rock and gravel crushing; Thicker lower end of the jaw die and the thinner upper end of the jaw die; Maximizes size of the maximum feed size of the cavity with the maximum nip angle; Wedge jaw die is the fixed one and the Standard jaw die is the movable one.

Tooth Profile: Anti Slab Tooth

Uses: Special jaws designed to crush slabby sedimentary rock; Can also be used when recycling concrete and asphalt slabs.

Tooth Profile: TIC Inserts Tooth

Uses: Special jaws designed to crush hard rock; Can also be used when recycling concrete, asphalt slabs, and mining industry.

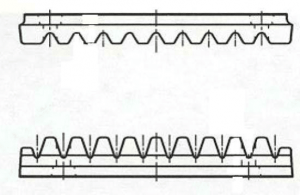

Tooth Profile: Corrugated Tooth

Uses: Laminar material; Small setting; High amount of fines; Cubical products

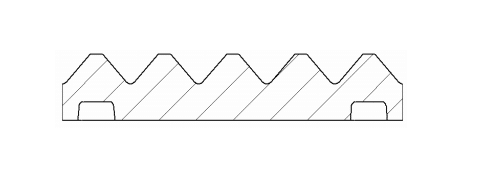

Tooth Profile: Coarse Corrugated Tooth

Uses: Laminar material; Abrasive material; High amount of fines; Large setting

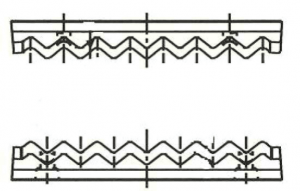

Tooth Profile: Sharp Tooth

Uses: Increased nip action; Laminar material; Abrasive material; Large amount of fine.

Tooth Profile: Heavy Duty Tooth

Uses: Extremely abrasive material; Increase liner life; No demands on particle shape; Can be combined with CC or ST for improve particle shape.

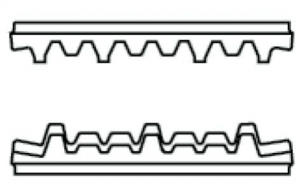

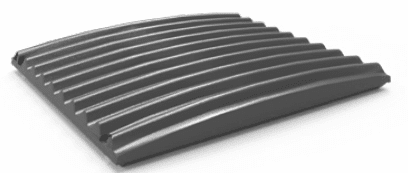

Tooth Profile: Wide Wave Tooth

Uses: Extremely flaky material; Less abrasive material, Muddy material; Good particle shape.

Tooth Profile: Wide Tooth

Uses: General applications; Abrasive rock; Less in stock due to that the Z-plate can be fitted on both sides.

Tooth Profile: S Tooth

Uses: Medium to Hard rock applications; Recycling applications; Grips material to allow better crushing; Available in 18% and 22%.

Tooth Profile: S Tooth

Uses: Recycling applications; Good grip on smooth flat surfaces; Available in 18%.

Tooth Profile: Shallow Tooth

Uses: Recycling and Soft Rock applications; Not available for all Models; Available in 18%.<