Recently, our foundry gets an order from USA customer, who needs sets large cone crusher concaves. its weight 6050kg, material ZGMn18Cr2.In addition to the requirements of conventional materials and sizes, customers also have strict requirements on the grain size of the body and the surface quality of the castings. Regarding the grain size, the customer requires that the grain size of the center position of the cast test block reach level 1. The size of the test block is 60mm × 60 mm × 40 mm.

Cone crusher concave is one of the main crusher wear parts in cone crusher.

Design Of The Large Cone Crusher Concave Casting Process

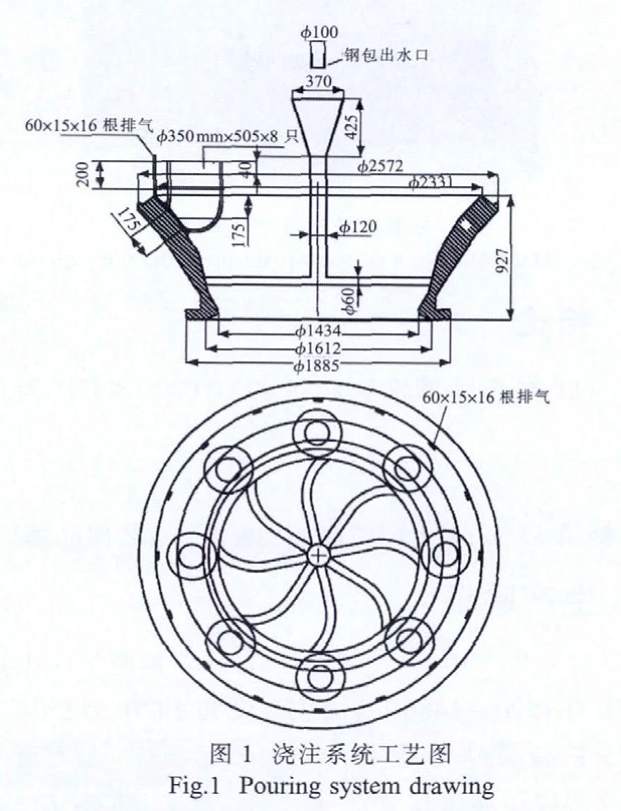

1.Design Of Pouring System

Because of the big size of this type cone crusher concave (upper diameter 2572mm, down diameter 1885mm, and height 927mm), and high-quality surface, we decide to use a bottom-injection pouring system. This system, it makes the molten steel fill smoothly and reduces the occurrence of surface defects in castings. The runner was set in the center of the casting and was laid with a 120 mm diameter refractory pipe.In order to ensure the requirement of bulk grain size, the casting temperature of high manganese steel must be reduced. The solidification interval of high-manganese steel is short. To ensure smooth filling on the basis of lowering the pouring temperature, 8 internal runners are used, which are laid with refractory pipes with a diameter of 60 mm. In the setting of the riser, in order to meet the needs of supplementation, a quasi-350 mm × 305 mm shaped heating riser was used. In its height direction, a thermal insulation jacket was set to increase the height by 300 mm, a total of 8 risers. The top box is set with 16 pieces of 50 mm × 16 mm exhaust. The sand material uses quartz sand which has been used in the factory for a long time. Water glass as a binder, carbon dioxide hardening process.

2.Melting And Casting Processes

The mass of the cone crusher concave is about 6050 kg, the mass of the pouring system is about 200 kg, the riser is about 2800 kg, and the total molten steel demand is above 9050 kg. According to our conditions of the foundry, the simultaneous operation of one 5 t and one 3 t intermediate frequency furnace can meet the demand for molten steel. In addition to strictly controlling the amount of regrind added, a high-quality slag remover is used at the same time. Fully deoxidize before tapping. Due to the low pouring temperature, bottom casting packages are used. Preheat the ladle before use. The tapping temperature is 1460 ~ 1480 ℃, and the pouring temperature is 1430 ~ 1450 ℃. Measure the temperature before tapping and pouring, and then pouring after reaching the pouring temperature. The pouring must be smooth, ensure continuous flow, and be completed within 1 minute, so as to avoid insufficient pouring and cold insulation defects at lower pouring temperatures. Pour the riser to fill, and then cover the riser with insulation. The box is loosened 10 hours after pouring and unopened after 80 hours.