High manganese steel is widely used in casting small-weight hammers (normally less than 90kg). However, for metal recycle shredder hammers (normally weight around 200kg-500kg), manganese steel is not suited. Our foundry uses low alloy steel for casting big shredder hammers.

Low Alloy Steel Shredder Hammer Material Element Selection

The alloy composition design must fully consider meeting the performance requirements of the alloy. The design principle is to ensure enough hardenability and high hardness and toughness. The internal stress of bainite is generally lower than that of martensite, and the wear resistance of bainite is better than that of martensite at the same hardness. The composition of the alloy steel as the following:

Carbon Element. Carbon is the key element affecting the microstructure and properties of low and medium alloy wear-resistant steel. Different carbon content can obtain a different matching relationship between hardness and toughness. Low carbon alloy has higher toughness but lower hardness, high carbon alloy has high hardness but insufficient toughness, while medium carbon alloy has high hardness and good toughness. In order to obtain high toughness to meet the service conditions of large and thick wear-resistant parts with large impact force, the range of low-carbon steel is 0.2 ~ 0.3%.

Si Element. Si mainly plays a role of solution strengthening in steel, but too high Si will increase the brittleness of steel, so its content is 0.2 ~ 0.4%.

Mn Element. China is rich in manganese resources and low in price, so it has become the main additive element of low alloy wear-resistant steel. On the one hand, manganese in the steel plays the role of solution strengthening to improve the strength and hardness of the steel, and on the other hand, it improves the hardenability of the steel. However, excessive manganese will increase the retained austenite volume, so the manganese content is determined to be 1.0-2.0%.

Cr Element. Cr plays a leading role in low alloy wear-resistant cast steel. Cr can be partially dissolved in austenite to strengthen the matrix without reducing the toughness, postpone the transformation of undercooled austenite and increase the hardenability of steel, especially when properly combined with manganese and silicon, the hardenability can be greatly improved. Cr has higher tempering resistance and can make the properties of thick end face uniform. so the Cr content is determined to be 1.5-2.0%.

Mo Element. Mo can effectively refine the as-cast microstructure, improve the uniformity of cross-section, prevent the occurrence of temper brittleness, improve the tempering stability, and impact toughness of steel. The results show that the hardenability of steel is significantly improved, and the strength and hardness of the steel can be improved. However, due to the high price, the addition amount of Mo is controlled between 0.1-0.3% according to the size and wall thickness of the parts,.

Ni Element. Ni is the main alloy element to form and stabilize austenite. Adding a certain amount of Ni can improve the hardenability and make the microstructure retain a small amount of retained austenite at room temperature to improve its toughness. But the price of Ni is very high, and the content of Ni added is 0.1- 0.3%.

Cu Element. Cu does not form carbides and exists in the matrix as a solid solution, which can improve the toughness of steel. In addition, Cu has a similar effect to Ni, which can improve the hardenability and the electrode potential of the matrix, and increase the corrosion resistance of steel. This is especially important for wear-resistant parts working under wet grinding conditions. The addition of Cu in wear-resistant steel is 0.8-1.00%.

Trace Element. Adding trace elements into low alloy wear-resistant steel is one of the most effective methods to improve its properties. It can refine as-cast microstructure, purify grain boundaries, improve the morphology and distribution of carbides and inclusions, and maintain sufficient toughness of low alloy wear-resistant steel.

S.P Element. They are harmful elements, which easily form grain boundary inclusions in steel, increase the brittleness of steel and increase the cracking tendency of castings during casting and heat treatment. Therefore, P and s are required to be less than 0.04%.

So the chemical composition for alloy wear-resistant steel is shown in the following table:

| Table: Chemical Composition For Alloy Wear-resistant Steel | ||||||||

| Element | C | Si | Mn | Cr | Mo | Ni | Cu | V.RE |

| Content | 0.2-0.3 | 0.2-0.4 | 1.0-2.0 | 1.5-2.0 | 0.1-0.3 | 0.1-0.3 | 0.8-1.0 | Rare |

Smelting Process

The raw materials were melted in a 1 T medium frequency induction furnace. The alloy was prepared by scrap steel, pig iron, low carbon ferrochrome, ferromanganese, ferromolybdenum, electrolytic nickel, and rare earth alloy. After melting, samples are taken for chemical analysis before the furnace, and the alloy is added according to the analysis results. When the composition and temperature meet the requirements of tapping, aluminum is inserted to deoxidize; during the tapping process, rare earth Ti and V are added for modification.

Pouring & Casting

Sand mold casting is used in the molding process. After the molten steel is discharged from the furnace, it is placed in the ladle. When the temperature drops to 1 450 ℃, the pouring starts. In order to make the molten steel fill the sand mold quickly, a larger gating system (20% larger than that of ordinary carbon steel) should be adopted. In order to improve the feeding time and feeding ability of the riser, the cold iron is used to match the riser and the external heating method is adopted to obtain the dense as-cast structure. The size of the pouring large shredder hammer is 700 mm * 400 mm * 120 mm, and the weight of a single piece is 250 kg. After the casting is cleaned, high-temperature annealing is carried out, and then the gating and riser are cut.

Heat Treatment

The quenching and tempering heat treatment process is adopted. In order to prevent the quenching crack at the installation hole, the local quenching method is adopted. The box-type resistance furnace was used to heat the casting, the austenitizing temperature was (900 ± 10 ℃) and the holding time was 5 h. The cooling rate of the special water glass quenchant is between water and oil. It is very beneficial to prevent quenching crack and quenching deformation, and the quenching medium has low cost, good safety, and practicability. After quenching, the low-temperature tempering process is adopted, the tempering temperature is (230 ± 10) ℃ and the holding time is 6 h.

Quality Control

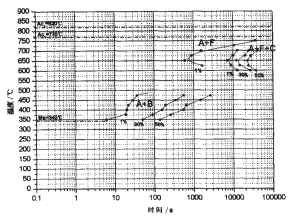

The main critical points of steel were measured by optical dilatometer dt1000, and the isothermal transformation curve of undercooled austenite was measured by the metallographic hardness method.

The TTT curve of the alloy steel

From the TTT curve line, we can know:

- There are obvious Bay regions between the transformation curves of high-temperature ferrite, pearlite, and medium temperature bainite. The C-curve of pearlite transformation is separated from that of bainite transformation, showing the appearance law of independent C-curve, which belongs to two “nose” type, while the bainite region is closer to S-curve. Because the steel contains carbide forming elements Cr, Mo, etc., these elements dissolve into austenite during heating, which can delay the decomposition of undercooled austenite and reduce its decomposition rate. At the same time, they also affect the decomposition temperature of undercooled austenite. Cr and Mo make the pearlite transformation zone move to a higher temperature and lower the bainite transformation temperature. In this way, the transformation curve of pearlite and bainite is separated in the TTT curve, and a subcooled austenite metastable zone appears in the middle, which is about 500-600 ℃.

- The nose tip temperature of the steel is about 650 ℃, the ferrite transition temperature range is 625-750 ℃, the pearlite transformation temperature range is 600-700 ℃, and the bainite transformation temperature range is 350-500 ℃.

- In the high-temperature transformation region, the earliest time to precipitate ferrite is 612 s, the shortest incubation period of pearlite is 7 270 s, and the transformation amount of pearlite reaches 50% at 22 860 s; the incubation period of bainite transformation is about 20 s at 400 ℃ and martensite transformation occurs when the temperature is below 340 ℃. It can be seen that the steel has good hardenability.

Low Alloy Steel Shredder Hammer Mechanical Property

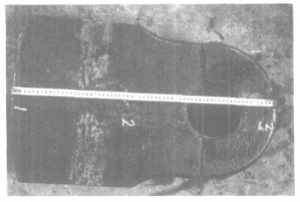

Samples were taken from the trial produced a large shredder hammer body, and a 10 mm * 10 mm * 20 mm strip sample was cut by wire cutting from the outside to the inside, and the hardness was measured from the surface to the center. The sampling position is shown in Fig. 2. #1 and #2 are taken from the shredder hammer body, and #3 are taken at the installation hole. The results of the hardness measurement are shown in Table 2.

| Table 2: Hardness Of The Shredder Hammers | |||||||

| Samples | Distance from surface/ mm | Average | Total Average | ||||

| 5 | 15 | 25 | 35 | 45 | |||

| #1 | 52 | 54.5 | 54.3 | 50 | 52 | 52.6 | 48.5 |

| #2 | 54 | 48.2 | 47.3 | 48.5 | 46.2 | 48.8 | |

| #3 | 46 | 43.5 | 43.5 | 44.4 | 42.5 | 44 | |

The picture of the shredder hammer

It can be seen from Table 2 that the hardness HRC of the hammer body (#1) is greater than 48.8, while the hardness of the mounting hole (#3) is relatively lower. The hammer body is the main working part. The high hardness of the hammer body can ensure high wear resistance; the low hardness of the mounting hole can provide high toughness. In this way, the different performance requirements of different parts are met. From a single sample, it can be found that the surface hardness is generally higher than the core hardness, and the hardness fluctuation range is not very large.

| Mechanical Properties Of The Alloy Shredder Hammer | |||

| Item | #1 | #2 | #3 |

| impact toughness(J·cm*cm) | 40.13 | 46.9 | 58.58 |

| tensile strength /MPa | 1548 | 1369 | / |

| extensibility / % | 8 | 6.67 | 7 |

| Reduction of area /% | 3.88 | 15 | 7.09 |

The data of impact toughness, tensile strength, and elongation are shown in Table 3. It can be seen from Table 3 that the impact toughness of the U-shaped Charpy specimen of the hammer is above 40 J / cm2, and the highest toughness of the mounting hole is 58.58 J / cm*cm; the elongation of the samples intercepted is more than 6.6%, and the tensile strength is more than 1360 MPa. The impact toughness of the steel is higher than that of the ordinary low alloy steel (20-40 J / cm2). Generally speaking, if the hardness is higher, the toughness will decrease. From the above experimental results, it can be seen that this rule is basically in line with it.

Microstructure

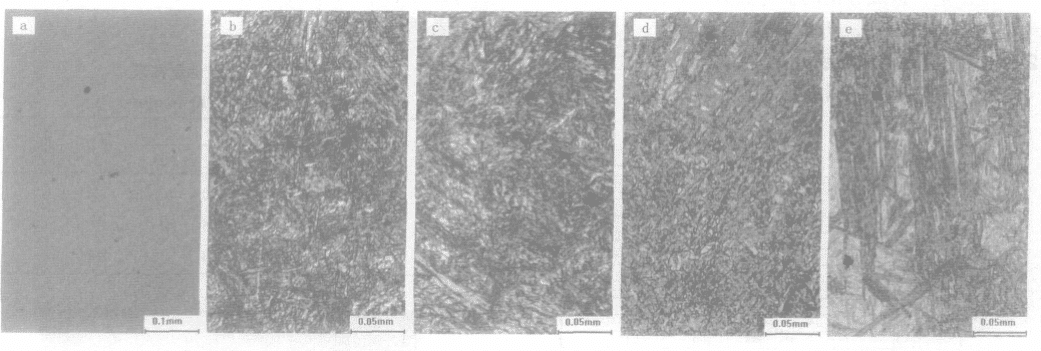

Microstructure a small sample was cut from the broken end of the impact sample, and then the metallographic sample was prepared by grinding, pre-grinding and polishing. The distribution of inclusions was observed under the condition of no erosion, and the matrix structure was observed after being eroded with 4% nitric acid alcohol. Several typical structures of alloy shredder hammers are shown in Fig. 3.

Fig. 3 The microstructures of the shredder hammer

Fig. 3A shows the morphology and distribution of inclusions in the steel. It can be seen that the number and size of inclusions are relatively small, without any shrinkage cavity, shrinkage porosity, and porosity. From figures 3b, C, D, and E, it can be seen that both near-surface and near center position

The results show that the hardened structure is obtained from the surface to the center, and enough hardenability is obtained. The microstructure near the center is coarser than that at the surface because the core is the final solidification site, the cooling rate is slow and the grains are easy to grow.

The matrix in Fig. 3b and C is lath martensite with uniform distribution. The lath in Fig. 3b is relatively small, and the lath in Fig. 3C is relatively thick, and some of them are arranged at 120 ° angle. The results show that the increase of martensite after quenching at 900 ℃ is mainly based on the fact that the grain size of the steel increases rapidly after quenching at 900 ℃. Fig. 3D and e show fine martensite and lower bainite with a small amount of small and granular ferrite. The white area is quenched martensite, which is relatively corrosion-resistant than bainite, so the color is lighter; the black needle-like structure is lower bainite; the black spot is inclusions.

Because the installation hole of the shredder hammer is cooled in air and the quenching temperature is low, the ferrite can not completely dissolve into the matrix. Therefore, a small amount of ferrite remains in the martensite matrix in the form of small pieces and particles, which leads to the decrease of hardness.

Results

After casting, we sent two sets of shredder hammers to our customer, one set of alloy wear-resistant steel shredder hammers, one set of manganese steel shredder hammers. Based on customer feedback, the alloy wear-resistant steel shredder hammers span life 1.6 times more than manganese shredder hammer.