Applications of Medium Manganese Steel on the Ball Mill Liners

Medium manganese steel was produced by reducing the carbon and manganese content of the high-manganese steel. Research results show that the matrix after water quench at the temperatures of 1050~1070 ℃ is austenite carbide (+0 ~W2 class). The medium manganese steel, whose wear resistance is better than that of the high manganese steel, can meet the requirements of strength and toughness in the non -working strong -impact conditions.

Since the invention of high manganese steel by RAHadfied in 1883, high manganese steel has been widely used in metallurgy, mining, building materials, and other industries. After more than one hundred years, it still occupies an important position in wear-resistant metal materials, but high manganese steel has not been strongly impacted. Under working conditions, due to insufficient work hardening capacity, its wear resistance cannot be effectively exerted. In order to improve the wear resistance of wear-resistant materials under non-strong impact conditions, high chromium cast iron has been developed at home and abroad, and successfully applied Manufacture of ball mill liners. The structure of high chromium cast iron is martensite + carbide + retained austenite. Due to the high hardness of the matrix, its wear resistance is excellent. However, due to the brittleness of carbides and high carbon martensite in high chromium cast iron Large, when used in the occasion of a certain impact, it is prone to peeling and fracture, which affects the normal operation of the equipment. Martensite, bainite steel, and austenitic steel have also been developed in China for non-strong impact conditions. The low hardness and poor hardenability result in an increase in service life. The material used to make the ball mill liner should have sufficient toughness to achieve good wear resistance. By adjusting the content of manganese and carbon in austenitic manganese steel to obtain an austenite structure at normal temperature, medium manganese steel can quickly achieve a deformed martensitic transformation under the impact of a load meets the above requirements.

One of our customer use Φ1.5×3 m ball mill, we design medium manganese steel mill liners to him, which help him to prolong the mill liners working life and decrease the cost.

Medium Manganese Steel Chemical Composition Design

1.Theoretical Basis

The matrix of medium manganese steel is austenite structure at normal temperature, but under impact wear conditions, the surface layer deforms α martensite and ε martensite, which is that medium manganese steel has good wear resistance under non-intense impact conditions The main reason for the performance. In order to obtain strengthened martensite, the manganese-carbon composition is designed with the starting temperature Ms of the martensite transformation and the temperature Md of the deformation-induced martensite point, so that the Ms point of the designed manganese steel is lower than zero degrees Celsius, and The Md point is higher than room temperature. The designed medium-manganese steel has an austenite structure after being water-toughened, and its austenite structure has low stability. It is at the critical point of the γ and γ + α phase regions. Under the impact load, The surface austenite is easy to be transformed into α-martensite and ε-martensite. Due to the strengthening of martensite during use, the strength of the abraded surface of the lining is increased, and the hardness is increased to meet the requirements of wear resistance. It is still austenite and meets the needs of toughness.

2.Chemical Composition

In order to save precious alloy resources and reduce the production cost of the liner, the designed manganese steel does not add other alloying elements. According to the formula:

Ms(℃)=550-361[C]-39[Mn]-35[V]-20[Cr]-17[Ni]-10[Cu]-5[Mo+W]+15[Co]+30[Al]

Ms(℃)≈-25~-35℃

Md(℃)≥Ms(℃)+(50+100) ℃

| Medium Manganese Steel Chemical Composition % | ||||||

| Element | C | Si | Mn | S | P | Re |

| Medium Manganese Steel | 0.65~1.15 | 0.20~0.80 | 5.50~8.50 | <0.050 | <0.080 | ≤0. 02 |

Medium Manganese Steel Casting Process

The medium manganese steel mill liner is made of water glass sand, and the shrinkage of the casting is 2.2%. The industrial production is carried out in a 3 t electric arc furnace using an oxidation smelting process. The charge is scrap steel, scrap iron, ferrosilicon (FeSi75), and ferromanganese (FeMn74). , FeMn78C2.0), after oxidation, reduction, and adjustment of the composition, the steel is produced under the condition that the slag is white slag, and the chemical composition is tested to make it within the required range, and the deoxidation is good, and the temperature of the molten steel meets the requirements. After the final deoxidation of aluminum, the steel is cast and the product is poured. After the middle manganese steel lining is poured, the riser is refilled once. The test block is poured in the middle of the pouring of the manganese steel lining. The test block is made according to the requirements of GB / T5680-1998. It is installed in the furnace together with the medium manganese steel lining board for heat treatment. The heat treatment uses a water quenching process. When the medium manganese steel lining board is heated to 650 ℃ at 50 to 70 ℃ / h, it is maintained for 2 to 3 hours, and then 50 to 100 ℃ / h. Raise the temperature to 1050 ~ 1070 ℃ for 3 ~ 5 hours, raise the holding temperature to 1100 ℃ 10 minutes before the end of the heating, and enter the water. The medium-manganese steel lining is cooled by water for 40 minutes and then discharged out of the pool for subsequent operations.

Medium Manganese Steel Microstructure and Mechanical Behavior

| Medium Manganese Steel Microstructure | ||

| Microstructure | Non-metallic inclusions | Grain size |

| Austenite + 0 ~ W2 grade carbide | 2~3 grade | 2~4 grade |

| Medium Manganese Steel Mechanical Behavior | |||

| σb /MPa | δ5 /% | αk /(J·cm-2) | HBS |

| 560~590 | 12~15 | 40~90 | 200~211 |

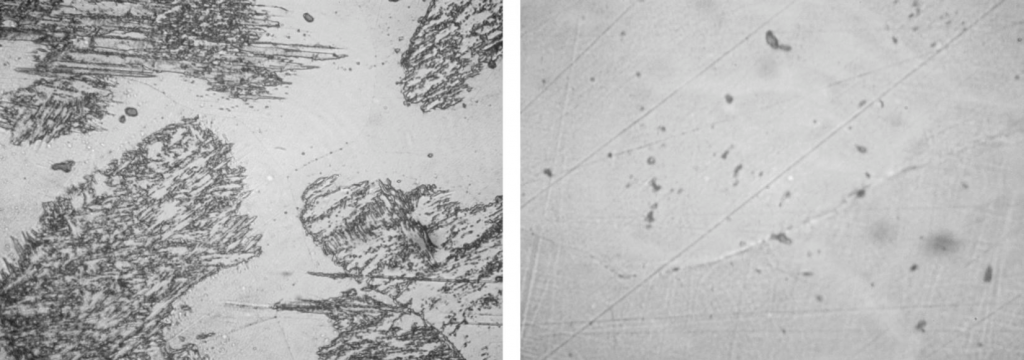

Medium Manganese Steel As-cast structure X500

Medium Manganese Steel Mill Liners Feedbacks

- By reducing the content of manganese and carbon and adjusting the matching of manganese and carbon, medium-manganese steel with a more stable austenite structure is obtained. Its composition is: 0.65% to 1.15% C, 5.5% to 8.5% Mn, 0.20% to 0.80% Si, < 0.080% P, < 0.050% S, under non-strong impact conditions, the steel has sufficient strength and toughness, and its wear resistance is better than high manganese steel.

- The developed manganese steel has the same manufacturing process as the high manganese steel. Quality control can be performed with reference to high manganese steel related standards. The manufacturing process is simple and the quality can be controlled stably.

- After water quenching at 1050 ~ 1070 ℃, the structure is austenite + 0 ~ W2 grade carbides. Under stress mutation, its strengthening ability is better than high manganese steel.

- The medium manganese steel lining has a tensile strength of more than 560 MPa and an impact toughness of more than 40 J / cm2. When used on a Φ1.5 × 3 m ball mill, it does not peel, deform, break, and operate safely and reliably. The service life is increased by 16% Promotion and use can produce good economic and social benefits.