Jaw Crusher Liner Improved Design

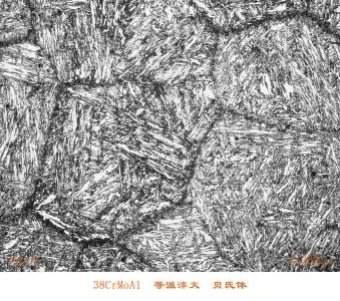

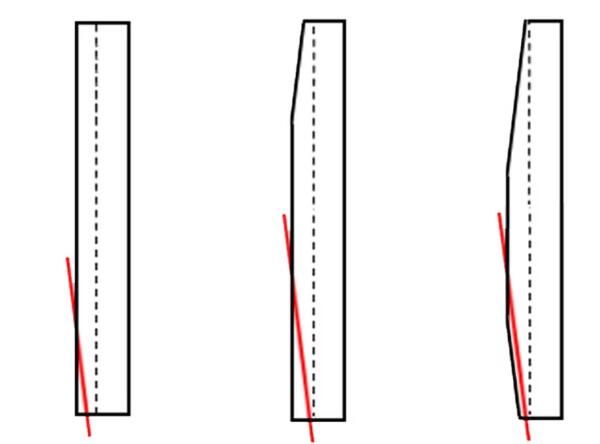

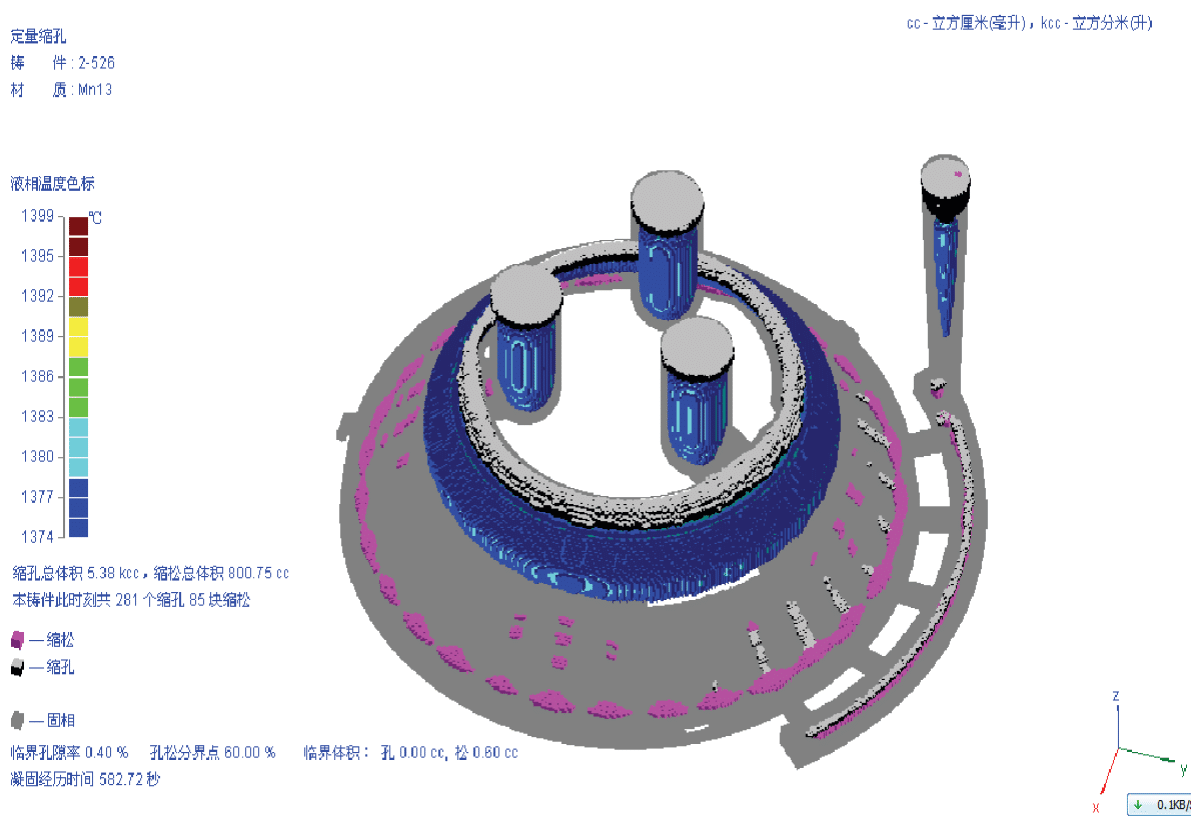

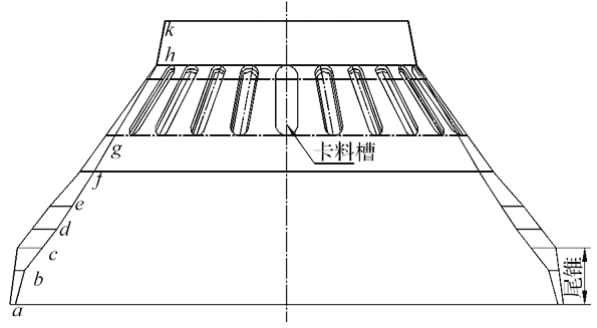

Our customer uses a PEF2100*1500 jaw crusher to crush ironstone. More than 8.7 million tons of iron ore are broken each year, and 2.2 million tons of iron ore powder is produced. The jaw crusher liner is the main jaw crusher wear part and the jaw crusher liner has frequent failures during use, has a…

Details