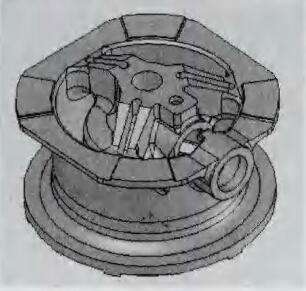

Large Cone Crusher Main Frame Shrinkage Improvement Practice

Stone crushing machinery is widely used in many departments such as mines, smelting, building materials, highways, railways, water conservancy, and chemical industry. With the development of the world economy, the revival of mining and other basic industries, the demand and increasing of crushers, customers’ requirements for product quality and performance are becoming higher and higher.…

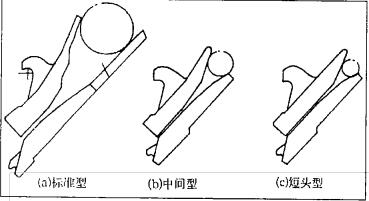

Details