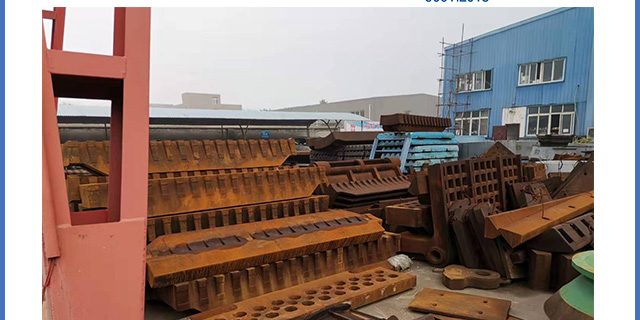

When we think of the mining industry scores of various kinds of jobs come to mind that needs to be achieved using a certain set of tools. It may include the extraction of the materials, putting them in the process of grinding, and even having them shredded. When it comes to shredding it is apparent that the perfect kinds of parts are needed to be put to use to make sure that the right sort of results is acquired. Among these, you will find a whole lot of variety that presents an entire set of options for you to consider when looking shredding something. Here are a few of them shredder wear parts listed for you to decide between.

Hammers:

It is inevitable for hammers to top the list when we are talking about shredders and their various parts. These are hardened materials that you can find made of various kinds of different materials. Those may include manganese for sure as well as martensitic steel and even chromium-nickel. That itself goes to show the extent of hardness that most hammers seem to have. When it comes to alloys to utilize in order to manufacture them as opposed to manganese one benefit is that the hammer is able to retain its original shape and so will not need added work hardening. Undoubtedly, this will go a long way to help it from wearing down too soon and will also ensure that the production rate is impressively high. If you are too worried about the fact that it might deform it is better to select this as opposed to manganese.

Grids:

Grids are of course ideal when it comes to shredding. Often companies try their best to make use of wear-resistant liners when manufacturing these grids so they can be more resistant to wear as well. This can help them provide more optimal performance while also lasting for a much longer time than they otherwise might. Since they are meant to be pretty tough they can take on a significant amount of stress that you may place on them and resist rather well.

Rotor And End Disc Caps:

When it comes to rotor and end disc caps they have actually proved just how useful they are several times over in the past. They can be made using alloy steel as well as manganese steel to add that extra bit of hardness that seems to be a requirement for shredder parts. It can also allow you to know which one would be better suited to you based on whatever use you might have for it. They are designed in a way that they can easily withstand the demands pertaining to shredders and provide the optimal value to customers.

Bottom Grates:

When you enter into a conversation about shredder wear parts grates are definitely going to be added into it. They are known to be the main addition when it comes to shredders and that is for a very good reason. There are known to be several different kinds of grates that you can use to get the ideal results. Some of them are half solid grates, bottom grates, back wall grates, reject doors, and solid grates as well as top grates. When we consider the bottom grates there is a perfect balance involved that promises both the right level of efficiency and strength. As there is a staggered formation of the openings that dot the grate a higher number of cutting edges are available for non-ferrous liberation. Not only will you get longer use out of them but they can even lessen the amount you need to pay and give you amazing benefits to go with it.

Conclusion:

When it is shredders that we are considering you must know that it has a whole lot of parts. All of them contribute to the shredding aspects in their own unique ways. You can decide on the ultimate usefulness of them all based on the features and their pros that are listed here. Whichever of them you do settle on will surely provide you with a great performance.