In the process of material extraction, apron feeders play an important part. This is because they are used to feed the materials to the equipment that is present in front of them at a constant rate. This constant rate of apron feeder keeps the process going and there is no need to manually feed the materials to the equipment again and again.

Just like every other component of the material extraction equipment, the apron feeder parts also go through a specific amount of wear and tear. Due to this, people get these parts from many manufacturers. If you are looking to get these parts in the most superior quality at great prices, we will provide you with any of the apron feeder parts.

What parts are necessary for an apron feeder?

If you are here to explore the apron feeder parts, here we will discuss the functionality of every part in an apron feeder.

Feeding skirt.

The feeding skirt is the part in an apron feeder that is used to store a limited supply of materials. This is like a funnel for the apron feeder and it allows the flow of materials on the apron feeder at a constant rate so that the apron feeder can supply the material ahead in the process.

The feeding skirt is made with high-grade metals to withstand the wear caused by the impact and friction of the materials.

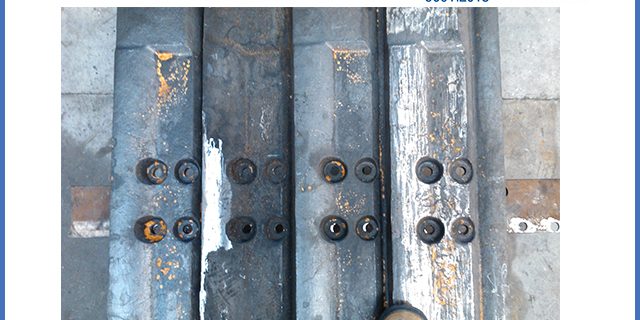

The pan plates in the apron feeder is one of the most important apron feeder parts. These are the horizontal pieces of metal that are connected to the mechanism of the apron feeder. This is the part that supplies the material from one end to another.

Chain.

To move the apron feeder pans, these pans are connected to this chain. The movement and the strength of the apron feeder pans are both dependent on this chain. Unlike other chains, this chain has industrial level hardness and strength to keep things going.

Chain support roller.

To keep the chain straight and tight, there is a chain support roller on both ends of the apron feeder. It also plays an important role in the alignment of the whole system.

Driving sprocket.

As the chain of the apron feeder could not be connected directly to the driving device, this part comes in between the chain and the driving device. The driver sprocket helps to supply the energy provided by the driving device to the chain to move it.

Tensioning device.

As every job of the apron feeders deals with different materials that have different weight and impact on the machinery, that is why the tensioning device is used to increase or decrease the tension of the system. It stiffens or softens the platform made by the apron feeder pans.

Driving device.

To make the whole system work, the driving device is used in every apron feeder. This is either an industrial motor or an industrial engine.

Frame.

To give the apron feeder a discrete shape with added stability and strength, all of the components are mounted or attached to a heavy and strong metallic frame.

How can you find the best apron feeder parts?

Each of the apron feeder parts plays a very important role in the functionality of the working of apron feeder. That is why you must only get the best quality apron feeder parts. If you are looking to get any of the apron feeder parts, we will provide you with the best quality at the best price.