Standard Materials

Most of the crusher wear parts are manufactured by Austenitic manganese steel and High chromium irons.

For jaw crusher:

- Jaw plates. The standard material is manganese steel which includes Mn14, Mn18, and Mn22.

- Cheek plates. The standard material is manganese steel which includes Mn14, Mn18, and Mn22.

For cone crusher:

- Mantles. The standard material is manganese steel which includes Mn14, Mn18, and Mn22.

- Concaves. The standard material is manganese steel which includes Mn14, Mn18, and Mn22.

- Bowl liners. The standard material is manganese steel which includes Mn14, Mn18, and Mn22.

- Feed cones. The standard material is manganese steel which includes Mn14, Mn18, and Mn22.

For gyratory crusher:

- Gyratory mantles. The standard material is manganese steel which includes Mn14, Mn18, and Mn22.

- Concave segments. Upper and middle stage liner standard material is manganese steel (Mn14, Mn18, and Mn22), the bottom stage liners standard material is low alloy steel and high chrome steel.

For HSI crusher:

- Blow bars. Standard material is high chrome steel (Cr27), based on crush material, the blow bars also manufactured by Manganese Steel, Chrome White Iron, Martensitic Alloy Steel, Chrome Iron + Ceramic Matrix, and Martensitic Alloy Steel + Ceramic Matrix.

- Impact plates. The standard material is high chrome steel (Cr15).

- Side plates. The standard material is high chrome steel (Cr15).

For VSI crusher:

- Rotor tips. The standard material is Tungsten Carbide inserts alloy steel.

- Wear plates. Most of VSI crusher plates standard material is chrome steel.

Austenitic manganese steel

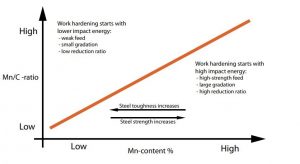

Austenitic manganese steel is a very tough and ductile material having a high impact toughness. Mn-steel is a rather soft material having an initial hardness of approx. 220-250 HV. The wear resistance of manganese steel is based on a work hardening phenomenon.

When the surface of the Mn-steel is under heavy impact or a compressive load, it hardens from the surface while the base material remains tough. The depth and hardness of the work-hardened surface vary depending on application and Mn-steel grade.

The work-hardened layer can be between 10 and 15 mm deep and hardness can be up to 600 HV in primary applications. In fine crushing applications, the work-hardened layer is thinner and hardness is usually around 350-500 HV.

The Mn/C ratio and amount of Cr are not only relevant when it comes to the wear resistance of the Mn-steel. The entire casting process needs to be well optimized to produce high-quality wear parts. Below are a few critical steps to producing high-quality Mn-steel castings.

It all begins with raw material selection where raw materials are carefully selected for melting in order to get the material analysis inside strict specifications and to reduce the number of certain impurities. During melting and pouring the temperatures are carefully controlled in order to achieve a fine grain structure for the castings. At the same time samples are taken to verify the material analysis and adjust if necessary. Melted metal is then poured into sand molds where the metal slowly solidifies. The molds have carefully designed feeding and gating channels to ensure solid castings.

Heat treatment is another critical step to producing ductile high-quality castings. Temperature, time, and quenching need to be well controlled in order to avoid grain boundary carbide formation. After the heat treatment has been completed, castings are machined according to strict tolerance to ensure a perfect fit for the crusher.

Besides the casting, the cavity shape has a significant effect on the performance of the crusher and the lifetime of wear parts. Cavity shapes are optimized by using sophisticated simulation tools and continuous testing and follow-up.

Utilization areas of different Mn grades

The standard manganese chemical composition, click here!

High chromium irons

This material group is offering classical solutions as well as more specialized solutions. These materials are of low cost and a good choice for many applications. The wear resistance is based on the hard carbides on the relative hard matrix, still, the composition and structure can be tailored considerably. Generally, high chromium irons are commonly used in abrasive wear applications

For the standard chromium chemical composition, click here!