Jaw plates include a fixed jaw plate and swing jaw plate, which are the main jaw crusher wear parts. They need to exchange very regularly. When & How to change jaw plates?

When to change jaw plates?

There are two situations that need to change the jaw plates.

- In order to prevent damage to the crusher parts, jaw plates need to be changed before they are worn through. Different kinds of jaw crushers have different situations. In some kinds of jaw crushers, jaw plates with a wedge retention design can wear to a thickness of 20-25 mm until they must be changed; In some other jaw crushers, jaw plates with locking wedges in the back can wear to a thickness of 60-65 mm until they must be changed. When to change jaw plates? It is based on your jaw crusher wedge retention design.

- Economic benefits and costs. After a long time of running, productivity will decrease because of the wear of jaw plates. So we need to calculate the ratio of economic benefits and cost. If the loss can cover the jaw plates price, we need to consider changing jaw plates.

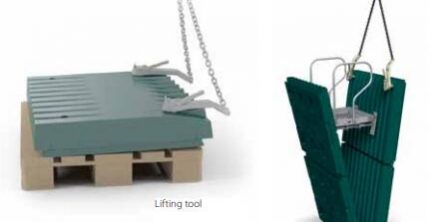

How to change jaw plates?

Jaw crusher wear parts need to be changed following the correct procedures to avoid risks. Different kinds of jaw plates need different ways to change jaw plates.

One-piece jaw die rotation and replacement

- After a new jaw dies installation, rotate the single-piece jaw dies when 30% of the tooth profile is worn.

- Rotate a second time when the tooth profile at the bottom of the jaw die is completely worn.

Two-piece jaw die rotation and replacement

- Worn-out jaw dies are removed from the bottom of the crushing chamber.

- Work hardened upper jaw dies are installed at the bottom of the crushing chamber.

- New jaw dies are installed at the top of the crushing chamber.